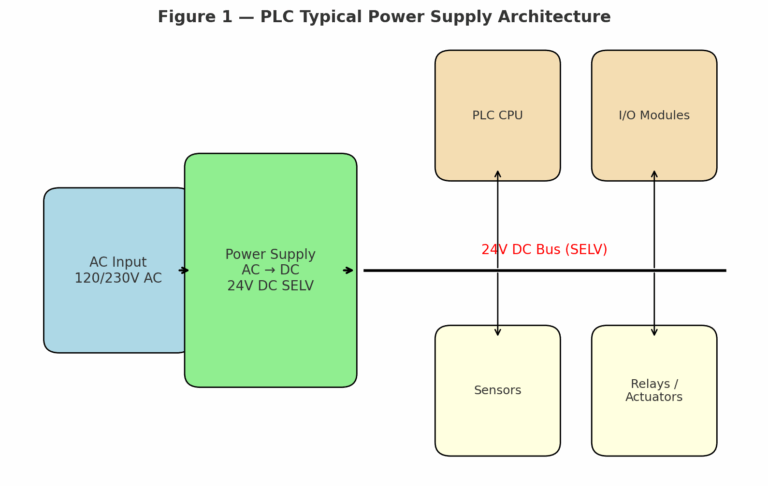

Programmable Logic Controllers (PLCs) are at the core of industrial automation. Among all supply voltages, 24V DC has become the global standard. This choice is not accidental—it is the result of careful consideration of safety, stability, electromagnetic compatibility, energy efficiency, universality, and cost-effectiveness.

1. Enhanced Safety

Safety is the top priority in industrial environments.

24V DC is within the Safety Extra-Low Voltage (SELV) range, which poses no significant risk of electric shock during operation or maintenance.

The lower voltage reduces arc generation and equipment damage risk during short circuits or faults.

This ensures a safer working environment for operators and technicians.

2. Stable Operation for Sensitive Devices

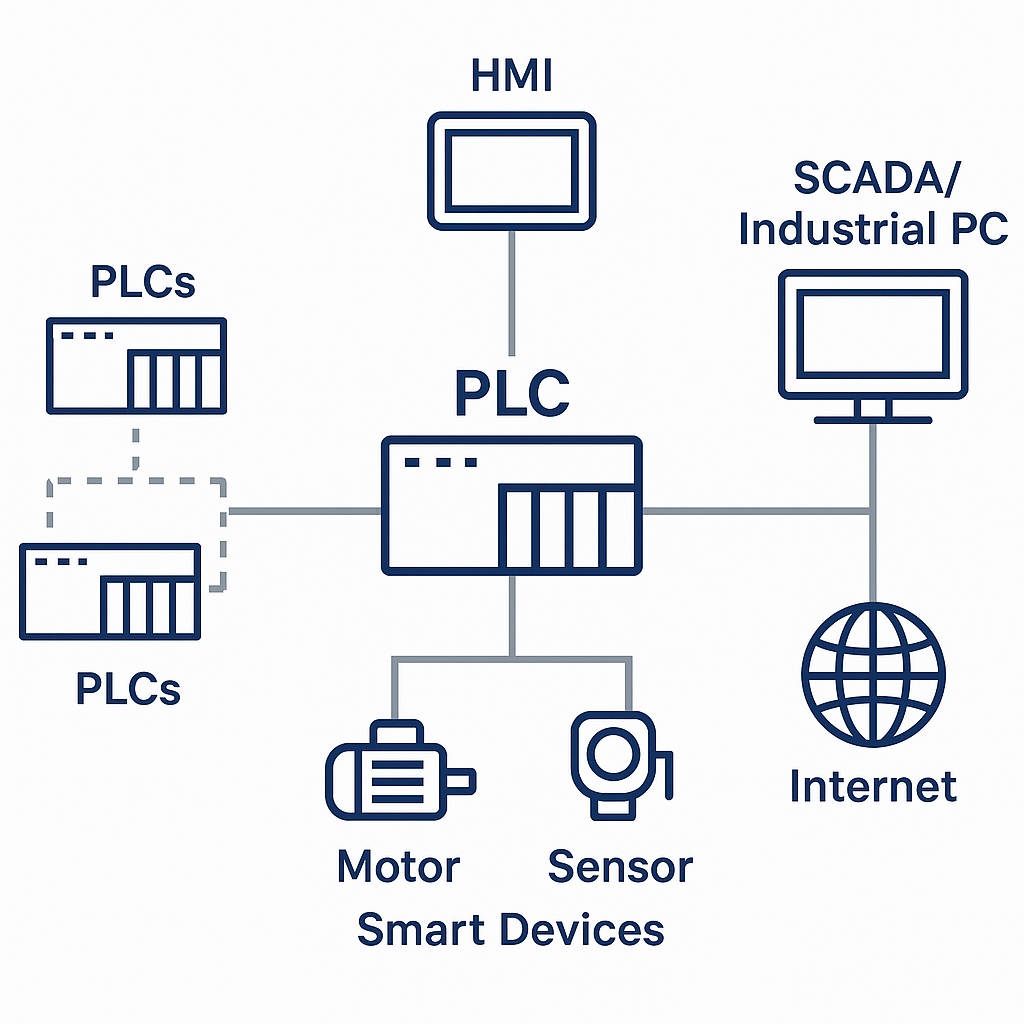

PLC systems rely on logic circuits, sensors, relays, and communication interfaces that are sensitive to voltage fluctuations.

24V DC provides a constant supply, unlike AC power which is subject to frequency and amplitude variations.

Stable DC supply minimizes false triggering and ensures reliable signal transmission.

This enhances system uptime and reduces unexpected downtime.

3. Superior Electromagnetic Interference (EMI) Immunity

Industrial plants are filled with EMI sources such as motors, drives, and welding machines.

24V DC has higher noise immunity, with sufficient signal margins to resist disturbances.

Unlike AC systems, DC does not introduce additional harmonics, improving communication reliability.

When combined with shielded cables and filters, 24V DC ensures clean signal transmission.

4. Energy Efficiency and Reduced Heat Loss

Long-distance cabling is common in factories. Compared with 12V DC:

24V DC reduces current by half for the same power, lowering I²R losses.

This improves energy efficiency and reduces heating of cables and terminals.

Less heat extends equipment lifespan and decreases cooling requirements.

5. Global Compatibility and Standardization

AC power supply standards vary by country:

North America: 120V AC / 60Hz

Europe: 230V AC / 50Hz

Japan: 100V AC / 50/60Hz

By using 24V DC as a universal standard, manufacturers only need to design one PLC platform, while simple power modules adapt to regional AC inputs.

This reduces design complexity and production costs.

Ensures compatibility across global markets.

6. Cost Reduction and Maintenance Efficiency

24V DC offers clear economic advantages:

Lower voltage allows for compact wiring, terminals, and fuses.

No need for bulky insulation, transformers, or high-voltage protective devices.

Mature global ecosystem ensures parts (power supplies, connectors, relays) are widely available and easily replaceable.

Conclusion

The adoption of 24V DC in PLC systems is a result of balancing safety, stability, EMI immunity, energy efficiency, universality, and cost-effectiveness. It has become the “golden standard voltage” in industrial automation, ensuring reliable operation while supporting global compatibility and reducing overall system costs.