In modern industrial automation systems, “sensors” and “transmitters” are ubiquitous. They act as the sensory and nervous systems of automation: one is responsible for “sensing the world,” while the other transmits the information. Though they often work together, their functions and principles differ significantly. Today, let’s discuss the key differences between sensors and transmitters.

1. Understanding Their Roles by Their Names

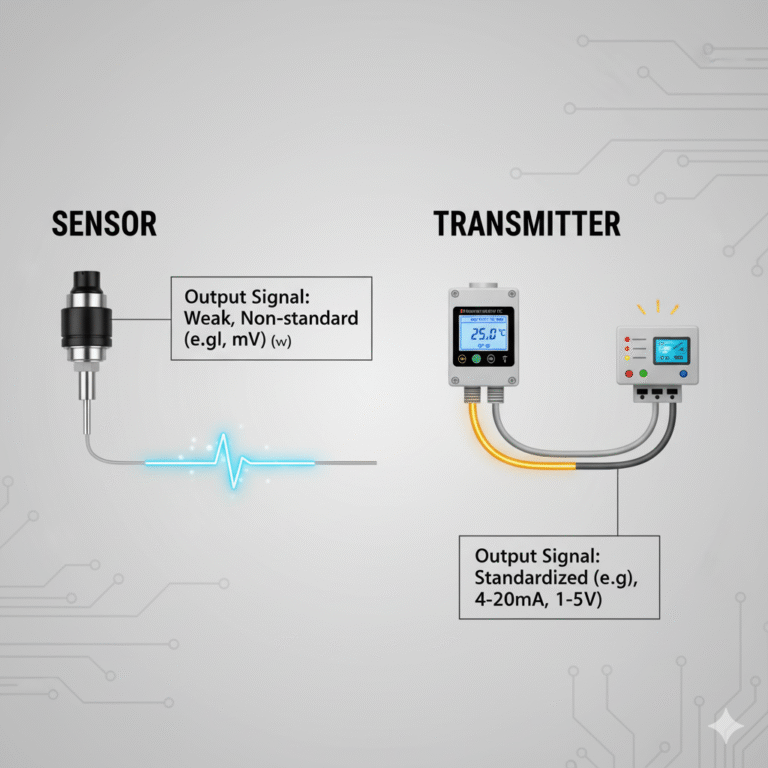

Sensor: As the name suggests, the sensor is responsible for “sensing” and “transmitting.” It captures physical quantities such as temperature, pressure, flow, and level, then converts them into electrical signals. In essence, a sensor is a combination of “sensing + conversion + transmission.” It consists of a sensitive element that detects physical changes and a converting element that transforms this information into an electrical output.

Transmitter: The transmitter, on the other hand, involves “transformation” and “delivery.” It converts the non-standard electrical signals received from the sensor into standardized signals (such as 4-20mA or 1-5V) and sends these signals to secondary instruments for display, control, or recording.

In summary, transmitters are developed from sensors to standardize signals and enable long-distance transmission.

2. Who Senses? Who Transmits?

Sensor: The sensor is the “front end” of information acquisition. It senses physical changes in temperature, pressure, flow, etc., and converts them into electrical signals. It is essentially the “eyes and ears” of an automation system.

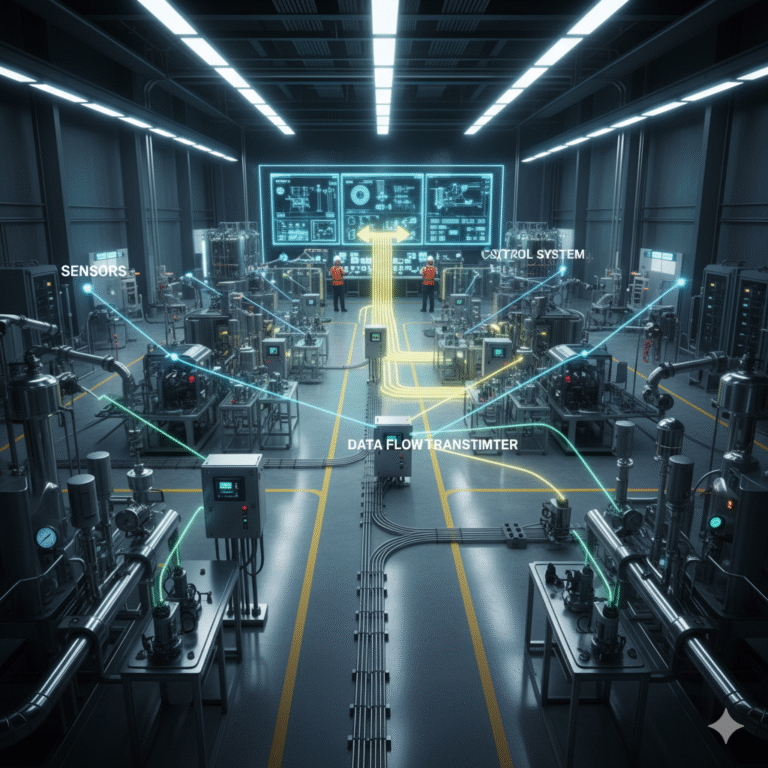

Transmitter: The transmitter acts as an “intermediate relay,” converting non-standard signals from the sensor into standard signals to ensure that these signals remain accurate over long distances. In an automated control system, they work together:

Sensor → Transmitter (standardizes and transmits) → Controller/Recorder (receives and processes).

3. Structural Differences

| Feature | Sensor | Transmitter |

|---|---|---|

| Main Components | Sensitive element, converting element, conversion circuit, auxiliary power | Measurement unit, amplifier, feedback unit |

| Output Signal | Non-standard, weak signals (e.g., mV) | Standardized electrical signals (e.g., 4-20mA or 1-5V) |

| Power and Wiring | Two-wire, three-wire, or four-wire configurations | Typically two-wire configuration, with power and signal combined |

| Application Position | Primary instrument (signal collection) | Between primary and secondary instruments |

4. Signal Output: A More Obvious Difference

Sensors typically produce weak, non-standard electrical signals, such as millivolt (mV) signals. Transmitters, however, provide standardized electrical signals like voltage (0-5V, 1-5V) or current (4-20mA, 0-20mA). These standardized signals enable direct connection to PLCs, DCS systems, or display instruments, which is why they are referred to as “transmitters.”

5. Analogy to the Human Body

The sensor is like the human sensory system (eyes, skin, ears, etc.), responsible for sensing changes in the environment, such as temperature or pressure. The transmitter, on the other hand, is like the nervous system, converting these sensory signals into neural signals that are transmitted to the brain (control system). Without sensors, the system cannot “see”; without transmitters, it cannot “understand” the information.

6. Integration of Sensors and Transmitters

With the rise of smart manufacturing, many devices now incorporate integrated smart transmitters. These devices combine both sensing (sensor function) and signal standardization/data processing (transmitter function). This integration allows for more efficient and precise automation systems capable of performing multiple functions such as measurement, control, and alarm triggering.

7. Conclusion

Sensors are responsible for “sensing the world,” while transmitters are responsible for “transmitting standardized signals.” Sensors are the foundation, and transmitters are the extension. Together, they enable automation systems to both “perceive and think.”