In the field of chemical manufacturing, safety is not only a moral responsibility but also a core element of sustainable operation. In China’s chemical safety management framework, the term “Two Key Points and One Major” forms the foundation of process safety control.

However, many companies know the concept but struggle with implementation. This article explains what it truly means, why it matters, and how to manage it effectively—from conceptual understanding to digital monitoring and continuous improvement.

1. The Concept: Three Elements of Hazard Control

(1) Key Hazardous Chemicals

These are chemicals that are flammable, explosive, or highly toxic, such as ammonia, chlorine, methanol, and ethylene oxide. They are subject to strict regulation due to their high reactivity and potential for catastrophic consequences.

(2) Key Hazardous Processes

Processes such as nitration, chlorination, sulfonation, or other reactions involving high temperature and pressure, unstable intermediates, or toxic by-products. Once process parameters deviate, chain reactions may occur rapidly.

(3) Major Hazard Installations

These refer to facilities that store, use, or produce large quantities of hazardous chemicals—such as tank farms, pressure reactors, or chemical warehouses. A single failure could lead to domino effects and regional-scale impact.

👉 Key takeaway:

These three categories are interlinked. Effective safety management must treat them as a unified system, not isolated items on a checklist.

2. Why “Two Key Points and One Major” Matter

Accidents Concentrate Around Them

A review of major industrial accidents shows that almost all were directly related to hazardous chemicals, dangerous processes, or major hazard installations.

Chain Reactions Escalate Quickly

A single failure point—like a leaking valve—can lead to fire, explosion, or toxic release. Once emergency energy (cooling, suppression, isolation) is consumed, escalation becomes uncontrollable.

High Potential for Serious Injury or Fatality (SIF)

These risks are not about frequency, but severity. Events with fatal or disabling potential must be prioritized even if they rarely occur.

3. Implementation Framework: The “1 + 5 + N” Model

1 Base: Risk Grading and Hidden Hazard Management

Risk Classification: Assess risk based on severity × likelihood (Red–Orange–Yellow–Blue).

Hidden Hazard Cycle: Identify → Classify → Correct → Verify → Review.

5 Core Management Lines

(1) Process Safety Management (PSM)

Includes HAZOP / LOPA analysis, P&ID consistency, operation discipline (SOP), mechanical integrity (MI), and management of change (MOC).

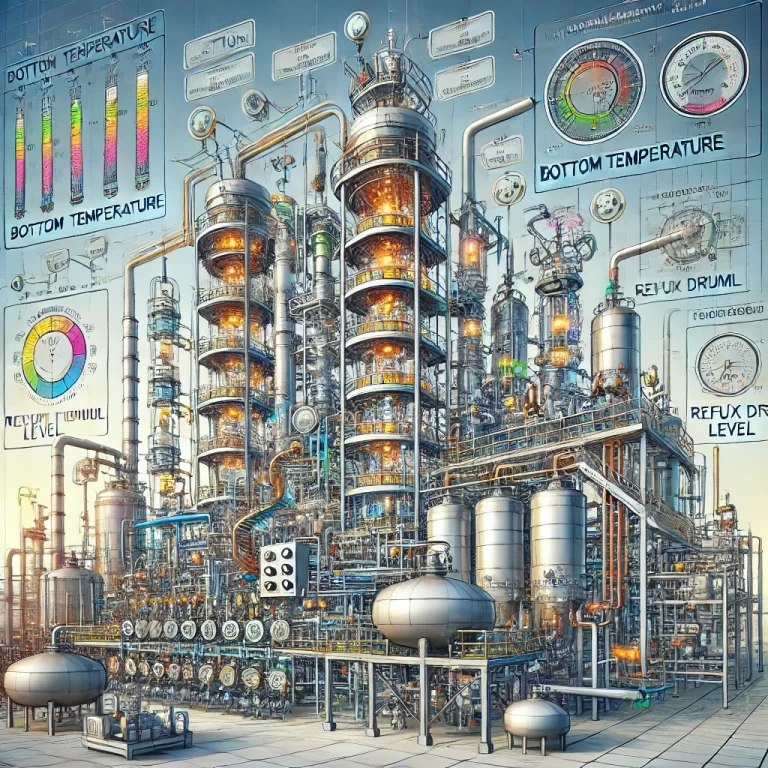

(2) Asset and Equipment Integrity

Covers static equipment (tanks, columns), rotating machinery (pumps, compressors), and instrumentation (SIS, interlocks).

(3) Human Factors and Permit to Work (PTW)

Focuses on safe work permits (hot work, confined space, lifting, excavation), LOTO (Lockout/Tagout), and fatigue management.

(4) Contractor and Third-Party Management

Qualification audits, induction training, supervision hierarchy, and performance reviews—plus a shared “blacklist” system for violators.

(5) Emergency Preparedness and Joint Response

Comprehensive plans, tabletop and field drills, coordination with fire brigades, environmental and medical responders.

N: Digital Enablers

Modern safety management increasingly relies on data and automation:

IoT Monitoring: Real-time tracking of temperature, pressure, level, gas concentration.

AI Early Warning: Pattern recognition to detect anomalies before failure.

3D Visualization: Mapping of major hazards, evacuation routes, and inspection paths.

Electronic Work Permits: Digital workflows with access control and live video verification.

4. Detailed Management Checklists

A. Hazardous Chemicals

Complete classification and up-to-date Safety Data Sheets (SDS).

Secondary containment and anti-static grounding in loading/unloading areas.

Real-time interlocks for over-temperature, over-pressure, or overfill.

Compatibility review for transport; ensure emergency equipment (showers, eyewash, respirators) is operational.

B. Hazardous Processes

Critical parameters (temperature, pressure, flow, concentration) have control and shutdown limits.

HAZOP review every 3 years or after major process changes.

Batch records and deviation logs are closed-loop managed.

Inert gas purging and contingency for cooling/stirring failure.

Layered protection via DCS and SIS.

C. Major Hazard Installations

Comply with zoning and spacing requirements.

Integrity of dikes, drainage channels, and overflow systems.

Fire and gas detection networks cover the entire area.

Conduct single-point failure and domino effect assessments.

Verify lighting, backup power, and emergency drills.

5. Management of Change (MOC)

Trigger scope: formula adjustments, raw material purity changes, equipment material upgrades, control logic modifications, repair plans, or contractor replacements.

Process flow:

Request → Multi-discipline review (process, mechanical, E&I, safety) → Trial run → Effect verification → Document update (P&ID, SOP).

Golden rule:

No commissioning before approval; during trial, apply limitations on speed, load, and capacity.

6. Contractor Management

Pre-qualification: Verify licenses, accident history, and key personnel certifications.

Induction training: Risk zones, permit rules, and emergency assembly points.

On-site control: Two-permit-three-system approach, hierarchical supervision, and extra approval for high-risk periods (night shifts, heat waves, storms).

Performance & exit: KPI alignment, violation penalties, shared blacklist mechanism.

7. Emergency Response and Drills

Dual system: Internal command + external coordination (fire, medical, environmental).

Frequency: One full-scale annual drill + monthly tabletop exercises.

Evaluation: Arrival time, tactical approach, communication redundancy.

Checklist: Spray/foam systems, E-stop devices, backup power, emergency supplies, personnel count accuracy.

8. Safety Performance Indicators

Lagging Indicators (Outcome-Based)

Incident and accident statistics by severity.

Production downtime due to safety events.

Environmental exceedances.

PSM Tier 1–4 event distribution (per API RP 754 or CCPS standards).

Leading Indicators (Proactive)

HAZOP action closure rate.

Interlock test compliance rate.

Work permit inspection pass rate.

Equipment inspection completion rate.

Alarm activation and suppression ratios.

Drill performance score.

Contractor violation rate.

👉 Build a red-yellow-green dashboard to visualize which plant areas or teams need urgent attention.

9. Common Pitfalls and Remedies

| Pitfall | Consequence | Countermeasure |

|---|---|---|

| Digital system deployed, but processes unchanged | False sense of security | Streamline SOPs and permissions before system rollout |

| KPI used only for punishment | Loss of engagement | Make metrics transparent and learning-oriented |

| Drills treated as formality | No true readiness | Add “blackout” and “surprise start” scenarios |

| Safety seen as the EHS team’s job | Weak accountability | Share responsibility across production, maintenance, and logistics—team leaders must own first-line safety |

10. Final Thoughts

Safety management is not about more paperwork—it’s about embedding discipline, awareness, and digital capability into every operation.

Start with one checklist, one HAZOP review, or one dashboard.

Because in chemical safety, details save lives, and systems sustain safety.