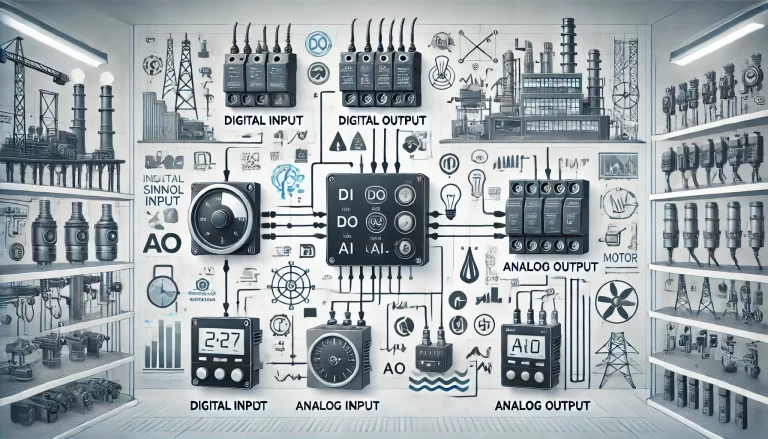

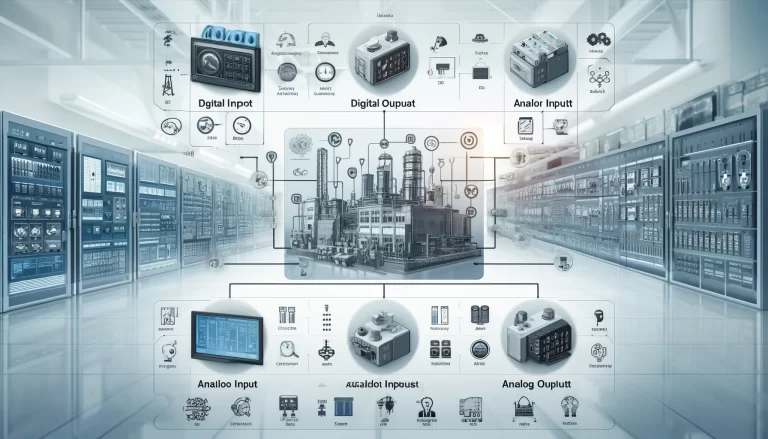

Industrial control systems rely heavily on signals to monitor and control equipment in various applications. The four main types of signals—Digital Input (DI), Digital Output (DO), Analog Input (AI), and Analog Output (AO)—play vital roles in ensuring smooth and efficient operations in manufacturing, process industries, and automation. Each of these signals serves a unique function, enabling the accurate transmission of data between sensors, controllers, and actuators.

1. Digital Input (DI)

Definition

Digital Input (DI) signals are binary signals received by the control system from external devices, indicating two distinct states: ON/OFF or 1/0. DI signals are typically used to monitor discrete events, such as the pressing of a button or the status of a switch.

How It Works

A DI signal is generated when an external device, such as a limit switch or a push button, sends a simple on/off signal to the control system. This binary signal is read by the system as either high (1) or low (0), corresponding to the device’s state. The control system then uses this information to perform specific functions based on the current status of the connected device.

Applications

- Switches and Buttons: DI signals can track whether a switch is in the on or off position, enabling the system to execute commands based on operator inputs.

- Sensors: Digital sensors, like proximity or photoelectric sensors, use DI signals to detect the presence or absence of objects in automated manufacturing processes.

- Alarm Systems: DI inputs can monitor safety interlocks and emergency stop buttons, ensuring immediate response to potential hazards.

2. Digital Output (DO)

Definition

Digital Output (DO) signals are binary signals sent from the control system to external devices to control their on/off state. These signals are crucial for controlling simple actions, such as activating an alarm or turning on a light.

How It Works

DO signals are generated by the control system to manage external devices in binary states. For instance, when a command is sent to activate a motor, a DO signal is transmitted as a 1 (on) to trigger the device. Similarly, when deactivation is needed, the signal switches to 0 (off), turning off the motor or other controlled devices.

Applications

- Lights and Alarms: DO signals can activate warning lights and sirens in response to hazardous conditions detected by the control system.

- Solenoids and Relays: Solenoid valves in fluid control systems or relays in electrical circuits use DO signals for binary control.

- Control Commands: These signals also serve to initiate processes, such as opening a valve or starting a conveyor belt in response to process requirements.

3. Analog Input (AI)

Definition

Analog Input (AI) signals are continuous signals received by the control system, representing real-world conditions, such as temperature, pressure, and flow rate. Unlike digital signals, analog signals can vary within a range, providing more granular and precise data.

How It Works

AI signals are typically transmitted as voltage (e.g., 0-10V) or current (e.g., 4-20mA) signals, proportional to the measured variable. The control system interprets these signals and converts them into engineering units (e.g., degrees Celsius or liters per minute) for analysis and decision-making. The 4-20mA range is especially popular because it can detect circuit issues: a signal below 4mA indicates a fault, while 20mA represents the upper limit of the sensor’s range.

Applications

- Temperature Measurement: Thermocouples and resistance temperature detectors (RTDs) send AI signals to measure the temperature in chemical processes or HVAC systems.

- Pressure and Flow Monitoring: Pressure transducers and flow meters provide continuous AI signals to maintain stable operation in water treatment, oil refining, and manufacturing industries.

- Level Detection: Liquid level sensors in storage tanks transmit AI signals to ensure optimal levels of materials, preventing overflow or shortage.

4. Analog Output (AO)

Definition

Analog Output (AO) signals are continuous signals sent from the control system to external devices, allowing precise control over their operation. AO signals are crucial in processes requiring variable adjustments, such as controlling the speed of a motor or the position of a valve.

How It Works

The control system generates AO signals, typically within a 0-10V or 4-20mA range, to communicate the desired operational setting to an actuator or controller. For example, a 12mA signal might represent half-speed operation on a motor, whereas a 20mA signal would represent full speed. This fine-tuned control allows the system to respond dynamically to changes in the environment or process.

Applications

- Motor Speed Control: Variable frequency drives (VFDs) adjust motor speed based on AO signals, crucial in conveyor belts and fans.

- Valve Positioning: Control valves adjust flow rates or pressures in response to AO signals, commonly used in pipelines and chemical reactors.

- Heater Control: Proportional control of heaters using AO signals allows gradual temperature adjustments, essential in temperature-sensitive manufacturing processes.

Summary of Key Differences

| Signal Type | Function | State/Value | Application Examples |

|---|---|---|---|

| DI | Receive binary input | 0/1 (Off/On) | Button states, limit switches, sensors |

| DO | Send binary output | 0/1 (Off/On) | Lights, alarms, relays |

| AI | Receive continuous input | 4-20mA or 0-10V | Temperature, pressure, flow sensors |

| AO | Send continuous output | 4-20mA or 0-10V | Motor control, valve positioning, heaters |

In conclusion, DI, DO, AI, and AO signals enable industrial systems to monitor and control processes with high precision. Digital signals provide simple, on/off states, perfect for binary control, while analog signals offer granular control for continuous variables, such as temperature and speed. Together, they create an interconnected framework that ensures safe, efficient, and automated operations across various industries, from manufacturing to energy production and beyond.