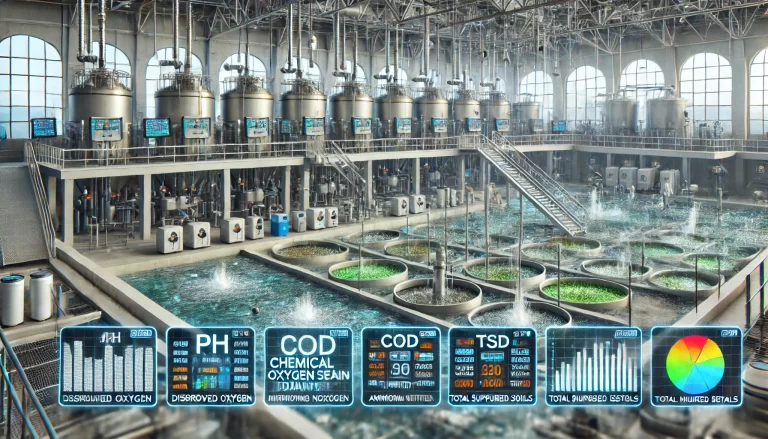

Wastewater treatment is a critical process for ensuring that water discharged into the environment meets environmental regulations and is safe for reuse or discharge. Efficient treatment requires real-time monitoring and precise control of various water quality parameters. This is where sensors come into play. Sensors used in wastewater treatment help automate processes, ensuring high-quality effluent and optimal operational efficiency. Below is a detailed overview of the key types of sensors commonly used in wastewater treatment control.

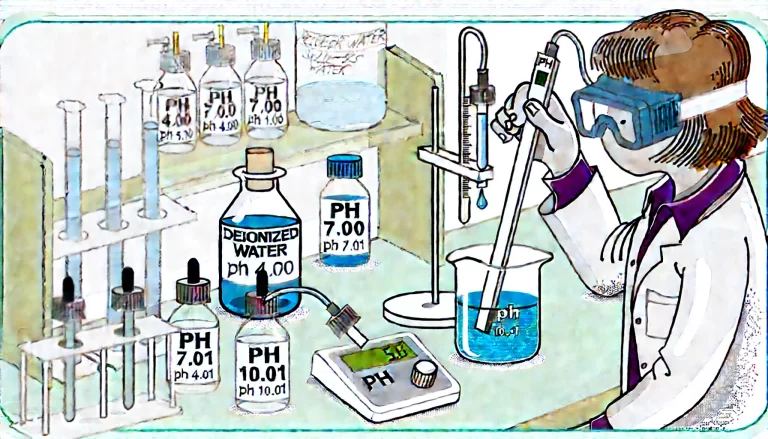

1. pH Sensors

pH sensors are essential in wastewater treatment plants for monitoring the acidity or alkalinity of the water. pH plays a crucial role in many biological and chemical processes during treatment. For instance, the effectiveness of disinfection by chlorine is pH-dependent, and biological processes such as nitrification and denitrification are most efficient within specific pH ranges.

pH sensors are typically based on electrochemical principles, using a glass electrode that measures the hydrogen ion concentration. A sudden change in pH can indicate potential issues in the treatment process, such as the failure of chemical dosing systems or an imbalance in biological treatment processes.

2. Dissolved Oxygen (DO) Sensors

Dissolved oxygen is a key indicator of the biological health of wastewater treatment systems, particularly in aerobic treatment processes. The presence of oxygen is essential for the survival of aerobic microorganisms that break down organic contaminants in wastewater. A lack of oxygen can slow down or halt the treatment process, while excessive oxygen can lead to energy waste and unnecessary operational costs.

Dissolved oxygen sensors work by measuring the amount of oxygen dissolved in the water, usually using either an electrochemical or optical method. These sensors help operators maintain optimal oxygen levels in aeration tanks and control the rate of aeration to ensure the efficiency of the biological treatment process.

3. Turbidity Sensors

Turbidity refers to the cloudiness or haziness of water caused by suspended solids, which can include bacteria, silt, or other particulate matter. Monitoring turbidity is crucial because high turbidity levels can interfere with the effectiveness of treatment processes like filtration and disinfection. In addition, untreated wastewater with high turbidity can be harmful to aquatic ecosystems if released into the environment.

Turbidity sensors typically use light scattering techniques to detect particles suspended in the water. A light source is directed through the water sample, and the amount of light scattered by the particles is measured by a detector. This value correlates with the level of turbidity. Regular monitoring ensures that the filtration systems are operating correctly and that the final effluent quality is up to standard.

4. Chemical Oxygen Demand (COD) Sensors

Chemical oxygen demand (COD) is a critical parameter in wastewater treatment as it represents the amount of oxygen required to oxidize organic compounds in the water. High COD levels indicate a high concentration of organic pollutants, which must be removed before discharge or reuse. COD is a key metric for assessing the efficiency of treatment processes like biological and chemical oxidation.

COD sensors often work by providing a colorimetric analysis, where a chemical reagent reacts with the organic compounds in the wastewater, causing a color change. The intensity of the color is then measured to determine the COD level. These sensors are used to monitor the overall organic pollution load and provide an early warning if the effluent’s organic content exceeds acceptable levels.

5. Ammonia Nitrogen (NH₃-N) Sensors

Ammonia nitrogen is a common pollutant in wastewater, particularly from industrial and agricultural waste. High levels of ammonia can be toxic to aquatic life, and they can interfere with the nitrification process, where ammonia is converted into less harmful compounds. Monitoring ammonia nitrogen is therefore crucial for both environmental protection and process control.

Ammonia nitrogen sensors work by detecting the concentration of ammonium ions (NH₄⁺) in water. These sensors often use ion-selective electrodes or chemical reactions to measure ammonia levels accurately. By continuously monitoring ammonia levels, operators can adjust treatment processes, such as aeration or dosing with nitrifying bacteria, to ensure the ammonia is effectively removed.

6. Total Suspended Solids (TSS) Sensors

Total suspended solids refer to the particles suspended in wastewater that can settle and form sludge during the treatment process. Monitoring TSS is important because high levels of suspended solids can indicate inefficiencies in sedimentation or filtration stages. Also, excessive solids in the final effluent can result in environmental pollution if not properly removed.

TSS sensors work by measuring the light transmitted through a water sample. Suspended solids scatter light, and this scattering can be quantified to estimate the concentration of solids in the water. By monitoring TSS levels, operators can ensure that the clarification and filtration processes are functioning optimally and that the treated water meets the required quality standards.

7. Chlorine Residual Sensors

Chlorine is often used in wastewater treatment for disinfection purposes. It is critical to ensure that adequate chlorine levels are maintained during disinfection to kill harmful pathogens. However, excessive chlorine can be harmful to aquatic life and may pose environmental risks if the treated water is released without proper dechlorination.

Chlorine residual sensors help measure the concentration of free chlorine remaining in the treated water after the disinfection process. These sensors typically work using electrochemical principles or amperometric techniques. Monitoring chlorine residuals ensures that the disinfection process is effective while minimizing the risk of chlorine toxicity in the environment.

Conclusion

The use of sensors in wastewater treatment control is vital for maintaining operational efficiency, ensuring regulatory compliance, and protecting environmental and public health. Each sensor type provides valuable data that allows operators to make real-time adjustments to the treatment process, optimize resource use, and achieve high-quality effluent. As the technology continues to advance, the integration of more sophisticated sensors will further improve the automation and precision of wastewater treatment systems.