In modern industrial automation, level detection is a critical aspect to ensure continuous production and safety. Whether it’s chemical storage tanks, powder silos, or ash systems in power plants, accurately monitoring the material’s position is essential for stable operations.

Among various measurement technologies, radio frequency capacitance (RFC) level switches are gradually becoming a mainstream solution in the industry due to their high precision, strong anti-interference capabilities, and wide applicability.

What is a Radio Frequency Capacitance Level Switch?

A radio frequency capacitance level switch is an intelligent measuring device based on the principle of impedance change using radio frequency signals. It detects the change in the electrical reactance (including capacitive and resistive components) between the probe and the material to determine whether the material has reached the preset level.

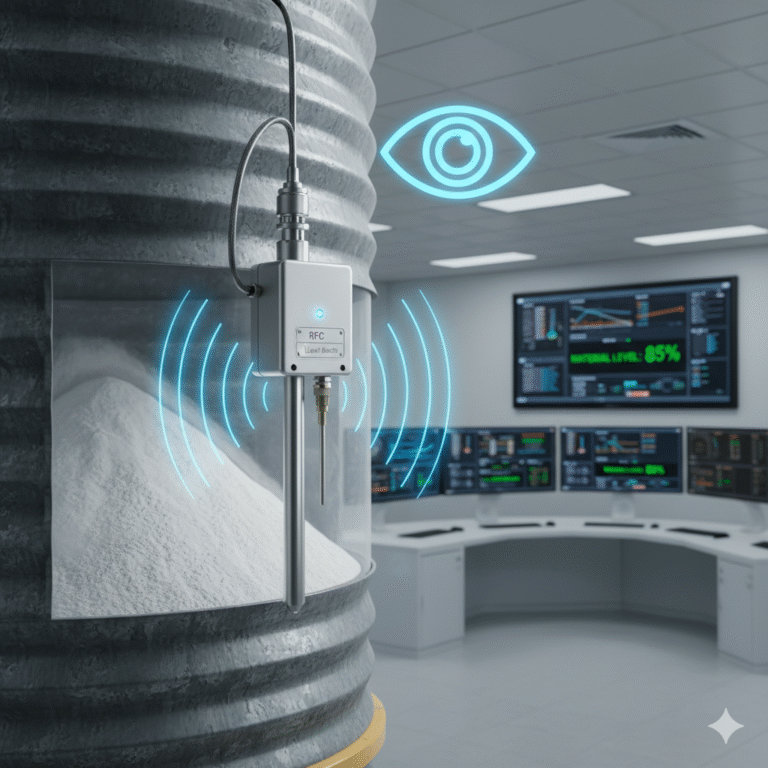

In simple terms, this device functions like an “electronic eye” in industrial production. It “senses” the presence and changes in material levels in real-time and sends feedback to the control system, enabling precise measurement and control.

Working Principle Explained

Bridge Circuit and Oscillating Signal

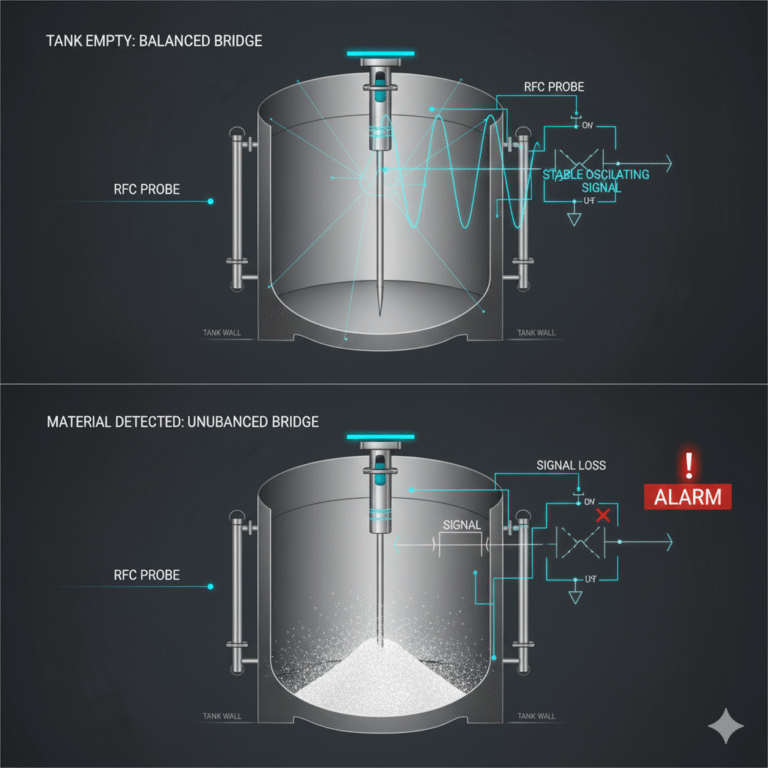

When the tank is empty, the electrical reactance between the probe and the tank wall forms a balanced bridge circuit, keeping the oscillating signal stable.

Once material covers the probe, the reactance changes, breaking the balance and causing the oscillating signal to disappear. The system then immediately issues an alarm or control signal to indicate the material has reached the set level.Electrical Isolation and Anti-Dryness Design

The probe’s measurement and protection electrodes are at the same potential, phase, and frequency, providing electrical isolation. If material accumulates on the probe, the potential difference becomes zero, which does not affect the measurement accuracy, thus greatly reducing false alarms.Signal Detection and Output Control

The imbalance signal is recognized by the electronic module, which outputs an alarm to monitor the material levels of powders and granules in real-time. This mechanism ensures stable operation even in environments with high dust levels or strong electromagnetic interference.

Key Advantages and Industry Applications

Non-contact Measurement, Safe and Reliable

Based on the electric field sensing principle, no direct contact with the material is needed. It is suitable for harsh environments such as high temperatures, high pressure, and strong corrosive environments, like chemical reactors and acid-base storage tanks.High Precision and Strong Stability

The device maintains accurate measurement even in complex conditions with dust or electromagnetic interference, widely used in industries such as cement, power, and pharmaceuticals.Wide Applicability

It can detect powders and granules, unaffected by material adhesion. For example, in the food processing industry, it can monitor sugar powder and edible oils simultaneously.Anti-interference and Long-Term Stable Operation

Radio frequency signals have a strong penetration ability through materials, offering excellent electromagnetic interference resistance, making the level switch ideal for automated production lines and continuous operation.Adaptation to Complex Environments

It operates stably in high temperatures, highly corrosive, or high-pressure environments, such as in metallurgical blast furnaces, petrochemical storage tanks, and battery raw material warehouses.

Installation and Usage Guidelines

To ensure long-term stable operation, strict adherence to the following installation and usage guidelines is required:

1. Installation Precautions

Avoid material inlet areas to prevent probe damage from material impact.

Maintain a distance of ≥500mm between instruments to avoid signal interference.

Ensure protection electrode insertion depth of ≥500mm to enhance anti-adhesion capabilities.

Take moisture prevention measures: Install cables with a downward curve to prevent rain or condensation from entering.

2. Usage Precautions

Installation location: Avoid placing the probe near feed inlets, mixers, or strong electromagnetic interference sources to ensure stable signal measurement.

Grounding: Proper grounding of the probe and shield is required to prevent signal drift or false alarms. For high-temperature, high-pressure, or highly corrosive media, choose probes made from materials resistant to these conditions and maintain a clean insulation layer to prevent measurement interference caused by material build-up.

Calibration: During setup, strictly follow the manual’s instructions for sensitivity and delay settings to prevent malfunctions.

3. Regular Maintenance and Fault Troubleshooting

Regular maintenance is essential for stable performance. The probe should be checked for scaling, adhesion, or corrosion every 3-6 months. Ensure proper shielding and grounding to avoid signal drift. Troubleshooting issues such as measurement errors, false alarms, or signal fluctuations should start with checking connections, sensitivity settings, and insulation. If problems persist, investigate the electronic module or probe for faults.

Typical Industry Applications

Chemical Industry: Monitoring levels in reactors to prevent corrosion risks.

Power Industry: Monitoring levels in coal silos and ash storage.

Metallurgical Industry: Precise detection of ores and materials in blast furnaces.

Environmental Protection: Wastewater treatment and garbage incineration process control.

Cement Industry: Powder storage and supply balance monitoring.

Food & Pharmaceutical Industry: Monitoring raw material storage in hygienic environments.

Future Development Trends

1. Smart Upgrade

AI algorithms will enable self-diagnosis, self-adaptation, and automatic calibration, adjusting measurement parameters based on material characteristics for more intelligent level monitoring.

2. Integration with IoT and Cloud Computing

Integration with cloud platforms will allow remote monitoring and early warning, enabling a transition from “manual monitoring” to “cloud-based intelligent management.” Staff can view real-time level data via smartphones or computers and proactively identify potential risks.

Conclusion

Radio frequency capacitance level switches are becoming a core monitoring device in industrial automation due to their high precision, anti-interference capabilities, and ability to adapt to complex environments. With the accelerating integration of AI and IoT technologies, these devices will provide even more efficient, safer, and smarter monitoring solutions for industrial production in the future.