In stable industrial operations, instruments are like the “nervous system” — when faults occur, they can range from minor disruptions in parameter monitoring to complete production stoppages. Modern instruments, however, are no longer in the “discrete component era.” With increasing integration, the core task of on-site instrumentation technicians has shifted from “chip-level repairs” to quickly and accurately identifying the fault range and restoring production in a timely manner.

This article, based on practical field experience, organizes a set of “immediate-use” troubleshooting techniques from five perspectives: Principles, Theories, Circuits, Process Integration, and Practical Methods. These techniques will help you rapidly transition from a “novice” to an “expert.”

1. Master the Instrumentation Principles

Mindset #1: Master the Instrument’s Principles — Don’t Let the Basics Trip You Up

The starting point for all troubleshooting is understanding “why the instrument operates in a certain way.” Many field issues appear complex but, at their core, stem from insufficient understanding of the principles.

Core Issue 1: Why is there a large error in the differential pressure transmitter?

The core logic behind measuring flow with a differential pressure transmitter is that “flow is proportional to the square root of differential pressure.” This means:

A 1% error in differential pressure results in a 10% error in flow. The error is not just from the transmitter itself; any problem along the full measurement path (e.g., from the throttling device (orifice/venturi) to the impulse lines to the transmitter) can introduce errors. Issues like blocked impulse lines, liquid accumulation, or incorrect installation of orifice plates are often more common than transmitter failure.

Practical Tip: Why must the balancing valve be opened before closing the high and low-pressure valves in a three-valve manifold?

Incorrect operation can lead to unidirectional overpressure. For example, closing the high-pressure valve directly can cause a sudden pressure surge in the impulse lines, potentially drifting the zero point or damaging the sensor. The correct sequence is to balance the high and low-pressure sides first to avoid isolating liquid or cooling fluids — a life-saving operation derived from the underlying principle.

Core Issue 2: Why do differential pressure level transmitters and glass level gauges show different readings, even when both instruments are functioning normally?

The key lies in the principle differences:

Glass level gauges operate based on the communicating vessel principle, meaning their readings are unaffected by medium density or temperature.

Differential pressure level transmitters are sensitive to changes in the medium’s density (e.g., from temperature fluctuations or composition changes), even if the level (H) remains the same. When this occurs, check if the medium density has fluctuated before suspecting instrument failure.

Core Issue 3: Why must thermistors be connected in a 3-wire configuration?

The reason is to eliminate the error caused by wire resistance. Thermistor temperature measurements use an unbalanced bridge, and using a 2-wire configuration introduces wire resistance into the measurement circuit, causing errors. A 3-wire configuration compensates for this resistance, minimizing the error.

2. The Evolution of Conservatism

Mindset #2: Strengthen the Theoretical Foundations — Resolve Common High-Frequency Issues like “Communication Failures” and “Signal Abnormalities”

About 80% of field “troublesome issues” can be quickly resolved through understanding the fundamental theories, such as HART communication protocols and signal circuits.

High-Frequency Pain Points: Why do you sometimes need to add resistors when the 475 communicator won’t communicate?

Understand the principle behind the HART protocol: HART is a superimposed 0.5mA audio digital signal (1200Hz = “1”, 2200Hz = “0”) on top of the 4-20mA DC signal. For proper signal recognition, there needs to be sufficient voltage amplitude. If the loop resistance is too low (e.g., directly connected to a power source), the voltage generated is insufficient, and the 475 communicator will fail to recognize the signal. In this case, add a 50Ω-100Ω resistor in series to maintain signal integrity.

Hidden Pitfall: Why does communication work in the workshop but fail in the field?

Most likely, the safety barrier does not support HART protocols. In the workshop, the circuit impedance may meet the requirements, but in the field, a regular safety barrier can block the digital signal, causing communication failure.

Multimeter Usage Mistake: Does a beep on the continuity setting mean the wire is intact?

No! The beep only indicates a low resistance (typically less than 50Ω). However, when measuring live circuits, the induced voltage might still cause a beep, which could lead to a false conclusion. Always disconnect power when measuring continuity, and use the voltage setting for signal measurements.

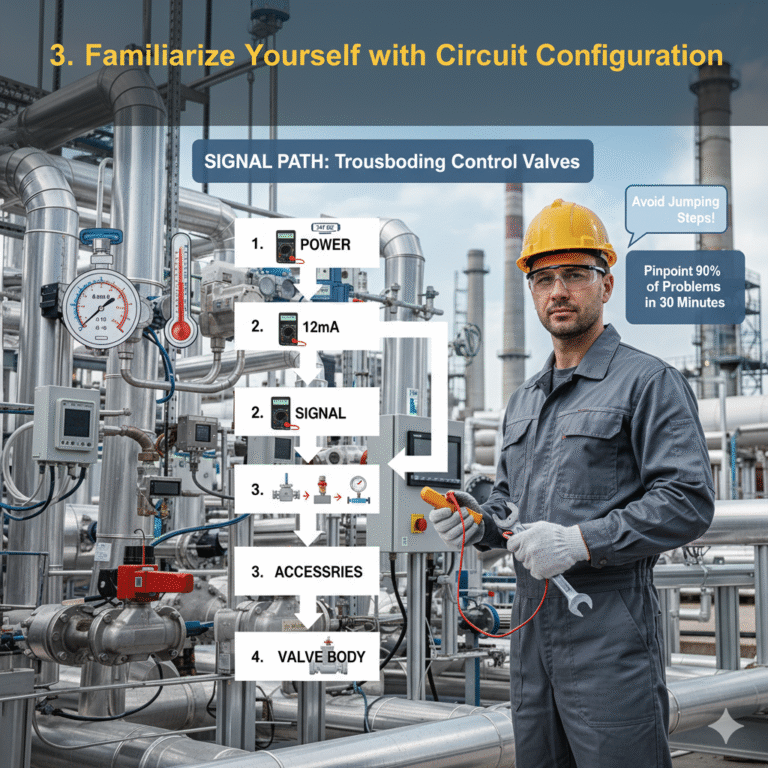

3. Familiarize Yourself with Circuit Configuration

Mindset #3: Understand the Circuit Configuration — Troubleshoot by Following the “Signal Path”

The biggest mistake in troubleshooting is jumping between unrelated issues. Understanding the “signal path” is key to ensuring no step is overlooked.

For example, consider troubleshooting a non-operating control valve:

Step 1: Check the power source (for an electric valve, verify the 24V DC power supply; for a pneumatic valve, check the air pressure).

Step 2: Check the control signal (use a multimeter to verify a 12mA signal on the input of the positioner).

Step 3: Check accessories (verify output from the positioner and check the solenoid valve for proper actuation).

Step 4: Check the valve body itself (inspect for obstruction or bent stem). This step should be last to avoid unnecessary disassembly.

Following this “power → signal → accessories → valve body” path will enable you to pinpoint 90% of problems within 30 minutes.

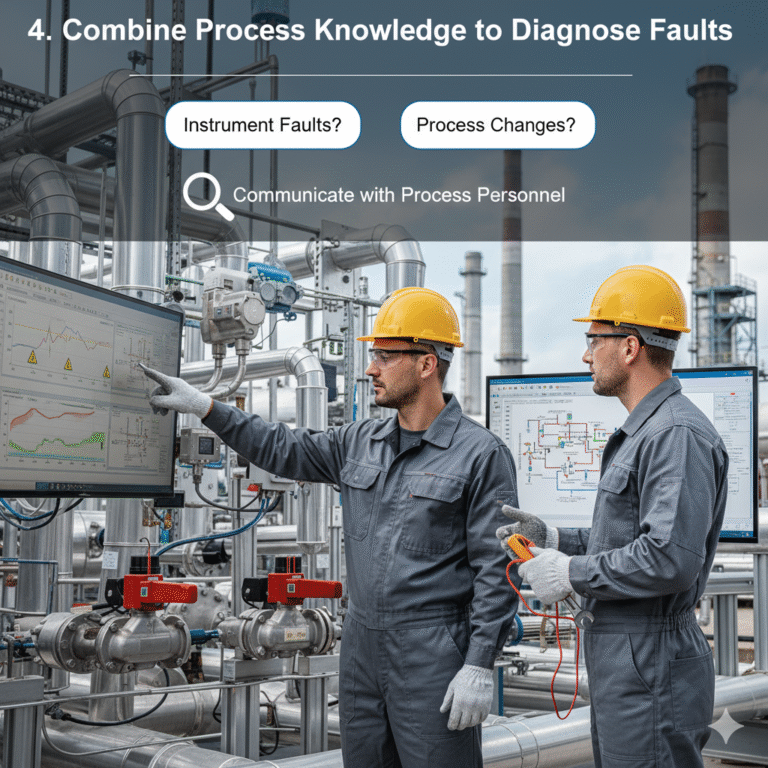

4. Combine Process Knowledge to Diagnose Faults

Mindset #4: Integrate Process Knowledge to Diagnose Faults — Don’t Let “Instrument Failures” Be Blamed on “Process Failures”

Often, “instrument failures” are actually signs of “process changes.” Learning to communicate with process personnel can save 80% of time and effort.

Case 1: Significant deviation in temperature readings — is the instrument faulty?

The process team reported inconsistencies in furnace tube temperatures, but the thermocouple was fine. The issue was traced back to varying levels of coke buildup on furnace tubes, which caused temperature discrepancies — a process issue, not an instrumentation fault.

Case 2: Why does the level in a vessel remain constant even with the valve fully closed?

At first glance, this might appear to be a level gauge or control valve failure, but further investigation revealed that a bypass valve was left open during process operations, allowing material to bypass the vessel.

5. Practical Skills for Quick Troubleshooting

Mindset #5: Use Practical Techniques — Narrow Down the Fault Range Quickly

On-site troubleshooting requires speed, accuracy, and stability. Mastering practical skills can dramatically improve efficiency.

Technique 1: “Segmentation” — Isolating the issue in segments:

For example, if a transmitter is not providing output:Disconnect the power and check if 24V DC is available at the control end (eliminate power supply issues).

Disconnect the signal line and use a signal generator to send a 4mA signal to see if the control system displays it (eliminate wiring issues).

Finally, confirm if the transmitter itself is faulty.

Technique 2: “Replacement” — The fastest way to troubleshoot:

If there is a spare instrument, replace the suspected faulty device (e.g., transmitter, positioner) to save time on circuit checks. Ensure that the spare parts are of the same model and calibrated.Technique 3: Troubleshooting New vs. Existing Devices:

For a newly installed differential pressure flow meter showing low readings, check for issues like reversed orifice plates or unvented impulse lines. For existing devices, focus on problems like blocked impulse lines, liquid accumulation, or zero drift.

Conclusion: The Core of Instrument Troubleshooting

The core of instrumentation troubleshooting is not about repair; it’s about diagnosis. With increasing instrumentation integration, technicians’ core competencies now lie in “quickly locating fault ranges,” not “repairing chips.”