Selecting the right diaphragm for a pressure transmitter is crucial, as it directly affects the accuracy, stability, longevity, and overall reliability of the measurement. In industries like chemicals and pharmaceuticals, where corrosive environments are common, diaphragm selection is even more critical for both safety and cost control. Choosing the right diaphragm material and type can significantly improve the performance and lifespan of pressure transmitters.

1. Types of Pressure Transmitter Diaphragms

1.1 Metal Diaphragms

Metal diaphragms offer excellent mechanical strength and temperature resistance, making them suitable for high-pressure and high-temperature environments. They are commonly used for industrial applications involving corrosive media such as acids, alkalis, salts, and organic solvents.

Stainless Steel Diaphragms (e.g., 316L): These diaphragms are relatively cost-effective and suitable for non-corrosive or weakly corrosive media (e.g., water, oil, and steam). They offer high mechanical strength and are used in industrial applications where corrosion is minimal.

Hastelloy: Hastelloy alloys, such as Hastelloy B and Hastelloy C, are known for their outstanding corrosion resistance in various environments:

Hastelloy B (Ni-Mo series): Excellent resistance to non-oxidizing acids like hydrochloric acid and sulfuric acid. However, it does not perform well in oxidizing acids (e.g., nitric acid). Common applications include the chemical and fertilizer industries.

Hastelloy C (Ni-Cr-Mo series): Offers both oxidation and reduction acid resistance, making it suitable for applications involving mixed acids (e.g., nitric and hydrochloric acid). It is often used in the fine chemicals industry and metallurgy.

Titanium: Titanium diaphragms are highly resistant to corrosion, particularly in environments containing chlorides, hypochlorites, and oxidizing acids (e.g., fuming nitric acid). However, they are not ideal for reducing acids like sulfuric or hydrochloric acid in dilute forms. They are commonly used in the chlor-alkali industry.

Tantalum: Tantalum diaphragms form a dense oxide layer that provides excellent corrosion resistance in most chemical media, except for hydrofluoric acid and strong bases. However, tantalum is more expensive than Hastelloy, and alternative materials like Hastelloy C are often preferred in non-extreme conditions. Tantalum is commonly used in the pharmaceutical and electronics industries.

1.2 Non-Metal Diaphragms

Non-metal diaphragms directly contact the media without the need for a filling liquid. They are suitable for corrosive and low-pressure environments (usually ≤ 1 MPa) and are particularly useful in industries where metallic ions may contaminate sensitive applications, such as food or pharmaceuticals.

PTFE (Polytetrafluoroethylene): Known for its outstanding corrosion resistance, PTFE can withstand virtually all chemicals, including strong acids, alkalis, and oxidizing agents. It also has a low coefficient of friction and excellent self-cleaning properties, making it ideal for measuring highly corrosive media. However, its mechanical strength is relatively low.

PVDF (Polyvinylidene Fluoride): PVDF has excellent chemical resistance and mechanical strength, making it suitable for a variety of acidic, alkaline, and organic solvent applications. It is commonly used in chemical, food, and pharmaceutical industries.

Ceramic (Alumina or Zirconia): Ceramic diaphragms are highly durable, resistant to wear, and stable in high-temperature, high-pressure, and corrosive environments. They are ideal for extreme conditions but are relatively brittle and can break easily.

2. Key Points for Selecting Pressure Transmitter Diaphragms

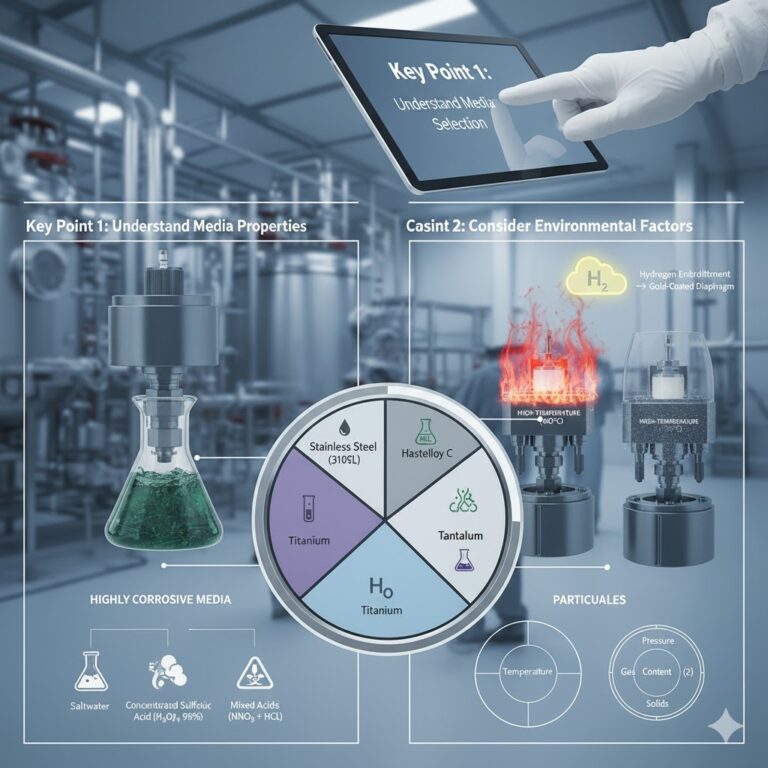

2.1 Understand the Properties of the Measured Media

The first step in selecting a diaphragm is to determine the chemical composition, concentration, and corrosiveness of the media. If the media is highly corrosive, such as saltwater or acidic environments, materials like Hastelloy (Hastelloy C), titanium, or tantalum are better options. Pay particular attention to the concentration of the media—e.g., for sulfuric acid, a concentration of 98% (oxidizing) requires a different diaphragm material than a diluted form (reducing).

2.2 Consider Environmental Factors

High-Temperature Environments: For environments with temperatures between 200°C and 400°C, choose diaphragms designed for high temperatures to prevent vaporization of the filling liquid, which could cause measurement errors.

Gas Environments: If hydrogen is present, particularly in concentrations of 70%–100%, gold-coated diaphragms should be selected to avoid hydrogen embrittlement.

Presence of Particulates: If the media contains solid particles, choose diaphragms with high wear resistance, such as ceramic or tungsten carbide-coated diaphragms.

2.3 Application Requirements

For applications requiring high-precision measurements, ensure the diaphragm thickness and shape meet the necessary accuracy standards. In industries like food and pharmaceuticals, non-metallic diaphragms such as PTFE or ceramic are preferred to prevent metal contamination. Semiconductor industries require high-purity materials, such as tantalum or PTFE.

2.4 Budget Considerations

Different diaphragm materials come at varying price points. Where possible, opt for cost-effective materials without compromising on measurement accuracy. For example, stainless steel diaphragms offer an affordable solution for less aggressive media.

2.5 Installation and Maintenance

Consider diaphragms that are easy to install and maintain. For example, flat diaphragm pressure transmitters are suitable for a wide range of environments and are easier to install and maintain. Modular transmitters allow easy diaphragm replacement, reducing maintenance cycles.

2.6 Confirm Diaphragm Structure Type

Standard Applications: For standard conditions, a “single-layer metal diaphragm” (e.g., Monel) offers low cost and fast response times.

Extreme Corrosive or High Viscosity Environments: Opt for “composite diaphragms” (e.g., Hastelloy C + PTFE) or “fully welded diaphragms” to prevent media from infiltrating the diaphragm or transmitter cavity.

2.7 Small-Scale Testing (Optional)

For unknown impurities or extreme conditions, perform a small-scale test by immersing a sample of the diaphragm material in the actual medium for 72 hours at the operating temperature and pressure. This will allow you to measure the corrosion rate and ensure material suitability (a corrosion rate of ≤0.1 mm/year is acceptable).

3. Pitfalls to Avoid

The “Hastelloy Solution” Fallacy: Hastelloy B and C have significant differences. Hastelloy B is not suitable for nitric acid, and Hastelloy C needs to be combined with PTFE for high-concentration HF environments. Do not blindly choose Hastelloy alloys without understanding the application.

“Tantalum is Always Better” Myth: Tantalum is expensive, and while it excels in many environments, it quickly corrodes in hydrofluoric acid. Choose the material based on the specific media properties, not just price or brand.

Ignoring the Impact of Temperature on Corrosion: A material that is corrosion-resistant at ambient temperatures may fail at high temperatures. For example, titanium corrosion rates increase significantly in hydrochloric acid at 80°C. Always consider temperature factors when selecting a diaphragm.

Conclusion

The key to selecting the right diaphragm for pressure transmitters is to match the media properties, material corrosion mechanisms, and operating conditions accurately. For instance, select Monel for hydrofluoric acid, Hastelloy B or titanium for hydrochloric acid, and Hastelloy C or titanium for nitric acid. In mixed acid scenarios, avoid single metal diaphragms and opt for composite materials like Hastelloy C + PTFE. Always verify all parameters of the media and material corrosion boundaries, and conduct small-scale tests if necessary.

Diaphragm selection is not based on “experience,” but on the scientific matching of material chemistry and media corrosion mechanisms. Choose the right diaphragm, and the equipment will function reliably with minimal maintenance.