In alkaline hydrogen production systems, separators play a crucial yet often overlooked role. Their primary function is to efficiently separate hydrogen gas from liquids (such as alkaline solution or water) at various stages, ensuring hydrogen purity, equipment safety, and system stability. The type of separator used depends on different operating conditions, and selecting the right one is key to ensuring safe and stable system operation while improving hydrogen production efficiency.

1. Common Separation Scenarios

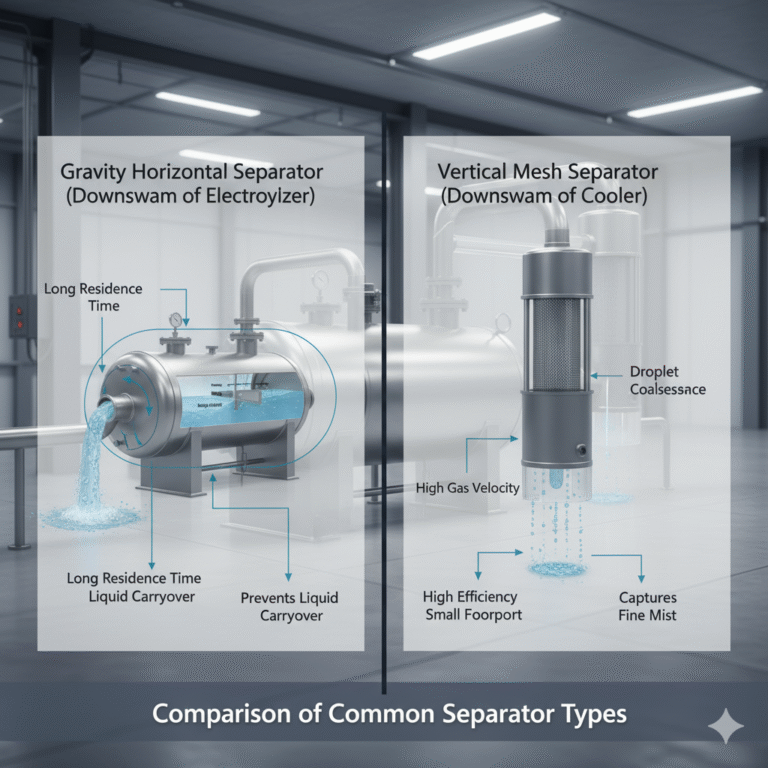

Separation Downstream of the Electrolyzer

In this stage, the separator is responsible for separating hydrogen gas from the alkaline solution. Typically, a gravity-type horizontal separator is used. These separators have a large volume, reduce flow velocity, and extend the gas-liquid residence time, preventing liquid carryover and corrosion, and ensuring cleaner separation of gas.Separation Downstream of the Gas Cooler

Here, the primary task is separating hydrogen gas from water to remove condensation. A vertical mesh-type separator is recommended. The mesh structure helps collect small water droplets, promoting coalescence and settling, thus ensuring higher purity hydrogen gas output.

Tip: For smaller hydrogen production rates (e.g., ≤20 standard cubic meters per hour), an integrated vertical structure combining a separator, scrubber, and cooler is often used. This compact design is easy to install and maintain, making it ideal for small skid-mounted systems.

2. Comparison of Common Separator Types

| Type | Advantages | Limitations | Typical Application |

|---|---|---|---|

| Gravity Horizontal | Long residence time, strong fluctuation resistance | Large footprint | Downstream of electrolyzer |

| Vertical Mesh | High efficiency, small footprint | Prone to liquid flooding, sensitive to gas velocity | Downstream of cooler |

| Blade Demister | Low pressure drop, good dirt resistance | Less effective for fine mist | High-flow systems |

| Centrifugal Separator | Compact, high-speed suitable | High pressure drop | High-pressure steam systems |

| Fiber Bed | Captures fine liquid droplets | High pressure drop, prone to clogging | Ultra-high purity hydrogen systems |

3. Design and Calculation Considerations

Gravity Separator: Efficiency via Time

A gravity separator consists of a body, head, anti-splash baffles, and flow plates. The key is residence time, typically 3–6 minutes. Anti-splash baffles and flow plates are used to slow down and extend the separation path, improving gas-liquid separation efficiency.Vertical Mesh Separator: Gas Velocity is Key

Essentially, this is a vertical version of the gravity separator, with a mesh separation layer at the top. Small liquid droplets coalesce and settle on the mesh, ensuring high-efficiency separation.Mesh Diameter: 0.22–0.28 mm

Mesh Height: 100–150 mm

Critical Formula (Souders–Brown Criterion):

If the gas velocity is too fast, liquid flooding occurs. If it is too slow, coalescence is insufficient. A 10–20% margin should be left based on actual gas volume and load fluctuations.

Pressure Drop and Corrosion Resistance

A lower pressure drop ensures more stable operation, but increased resistance due to fouling must be considered.Recommended Materials: 304/316L stainless steel. For chlorine-containing or high-concentration alkaline environments, duplex steel or anti-corrosion coatings are recommended.

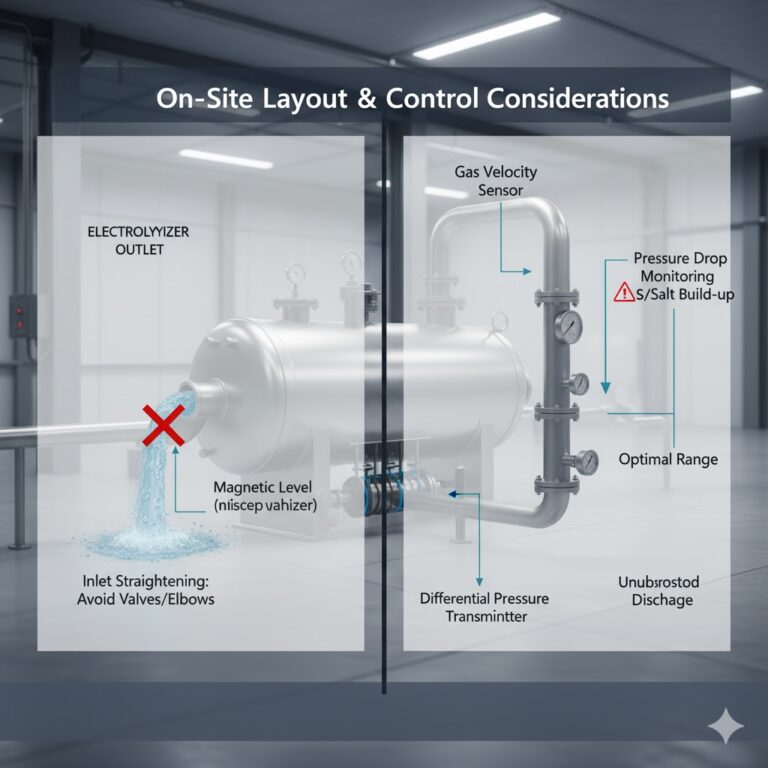

4. On-Site Layout and Control Considerations

Inlet Straightening

At the inlet of gravity separators, avoid placing valves or elbows that may cause sudden changes in flow direction or velocity, as they can negatively impact separation efficiency.Control Gas Velocity

For vertical mesh separators, gas velocity should be kept within an optimal range. If the velocity is too high, liquid droplets may be blown away; if it’s too low, effective turbulence won’t form, leading to reduced separation efficiency.Liquid Level Control

Use magnetic level indicators or differential pressure transmitters to prevent liquid flooding.Pressure Differential Monitoring

If the pressure drop in the mesh separator increases, it may indicate clogging or salt build-up. In such cases, a cleaning procedure should be initiated.Automatic Drainage

Condensation water and alkaline solution discharge must be unobstructed to prevent carryover and re-contamination.Insulation and Anti-Freezing

In low-temperature operations, heating elements should be installed in the liquid phase area to prevent freezing.

5. Summary

Downstream of Electrolyzer: Use gravity-type horizontal separators.

Downstream of Cooler: Use vertical mesh separators.

Small-Scale Systems: Recommended to use integrated vertical structures.

Control flow velocity and direction to ensure efficient and stable separation.