In industries such as chemical production, paint manufacturing, and energy transportation, concepts like flash point, fire point, and auto-ignition temperature (AIT) are not abstract physical phenomena but critical temperature thresholds that define safety and risk levels. Understanding their differences and relationships is the foundation of fire and explosion safety design, storage, and transportation management.

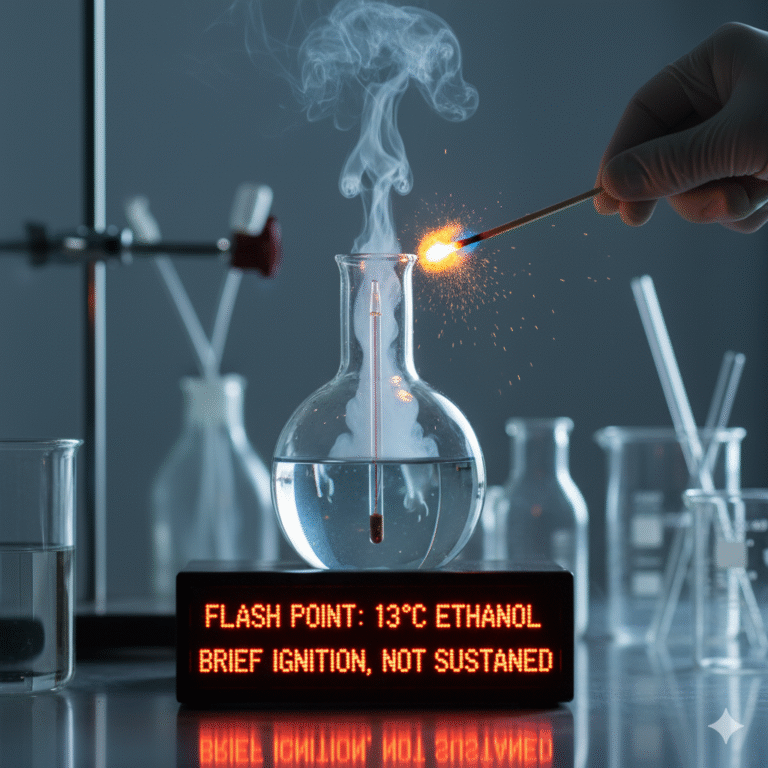

1. Flash Point

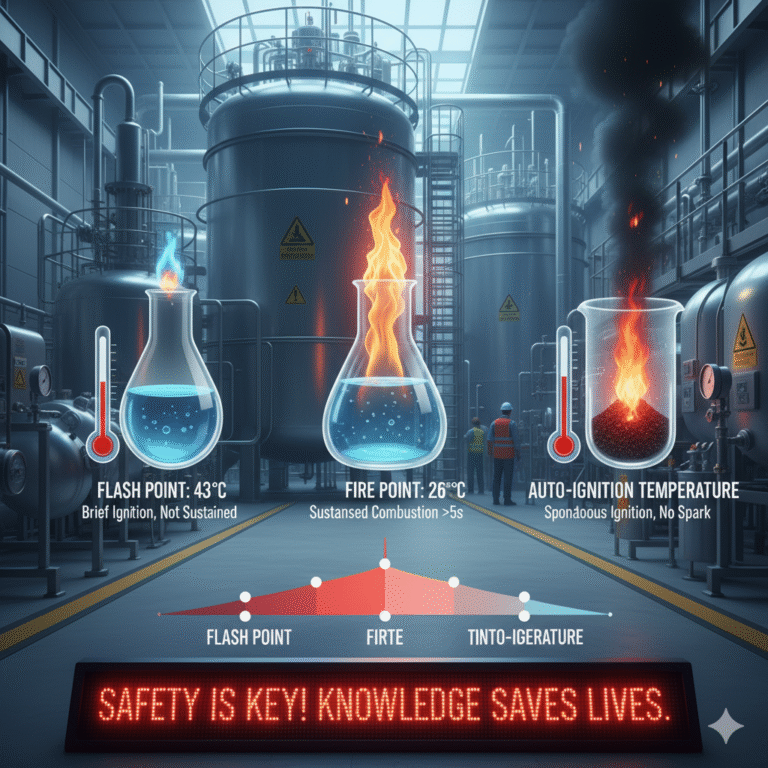

The flash point is the lowest temperature at which a liquid releases enough flammable vapor to form a mixture with air that can ignite momentarily upon contact with a spark or flame, but cannot sustain combustion. This is determined under specified test conditions, such as the closed cup method (GB/T 261-2021).

As the temperature increases, the liquid begins to vaporize. The vapor mixes with air, creating a combustible mixture that briefly ignites when exposed to a spark, but the flame extinguishes quickly due to insufficient vapor generation. This brief ignition point is the flash point.

Common Examples:

Gasoline: around -43°C

Ethanol: around 13°C

Diesel: around 55°C

Lubricating oil: around 200°C

Industrial Applications:

Hazard Classification: Flash point < 23°C → Extremely flammable liquids; 23-60°C → Flammable liquids

Design & Storage: Determines fire rating, ventilation, and explosion-proof electrical zones.

Transportation: Flash point is a key factor in classifying hazardous liquid goods for transportation under the UN Dangerous Goods Regulations.

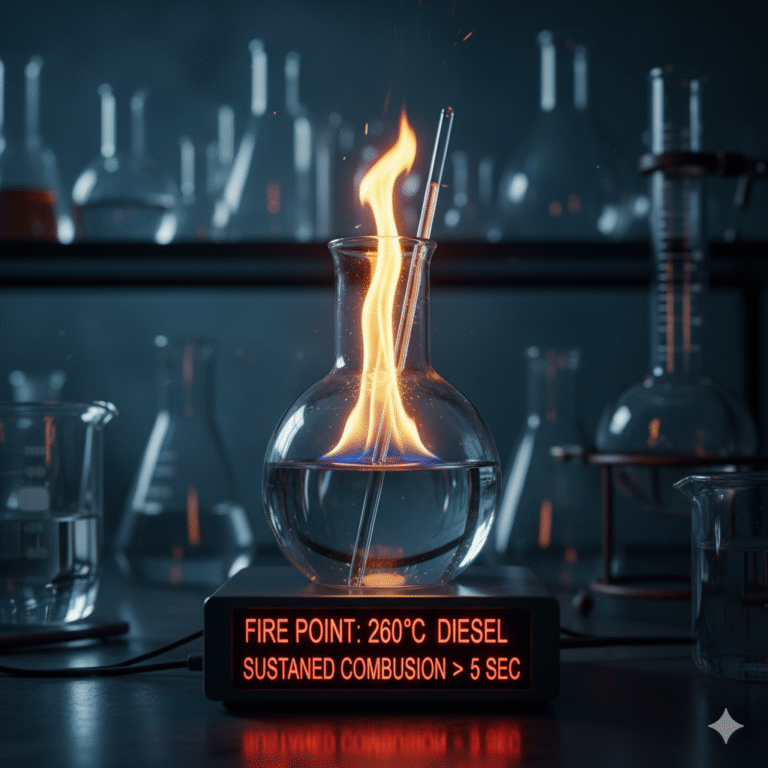

2. Fire Point

The fire point is the lowest temperature at which a liquid or solid, upon external ignition, will continue to burn for more than 5 seconds.

At the fire point, the heat released during combustion is sufficient to sustain the generation of flammable vapor even after the ignition source is removed.

Common Examples:

Diesel: around 260°C

Wood: around 300°C

Paper: around 233°C (famously referenced in Ray Bradbury’s Fahrenheit 451)

Industrial Applications:

Thermal Safety: Coating, ink, and lubricating oil drying temperatures must stay below the fire point.

Explosion Prevention: High-temperature equipment must operate below the fire point to prevent combustion.

Accident Analysis: Fire point helps determine the origin of fires and conditions for sustained combustion.

3. Auto-Ignition Temperature (AIT)

The auto-ignition temperature (AIT) is the lowest temperature at which a combustible material will spontaneously ignite without any external flame or spark, due to internal heat generated from chemical reactions.

At this temperature, the rate of heat accumulation exceeds the rate of heat dissipation, causing the material to reach a critical temperature that leads to self-ignition.

Common AIT Examples:

Gasoline: around 280°C

Diesel: around 320°C

Ethanol: around 363°C

Wood: around 300°C

Lithium-ion battery electrolyte: around 200°C

Industrial Applications:

Coal Storage & Transport: Coal dust can self-ignite due to heat buildup and oxidation; proper ventilation and cooling are crucial.

Lithium Battery Manufacturing: Low AIT in electrolytes makes “thermal runaway” a key risk.

Oil-soaked Waste: Rags or oil-soaked cloths can heat up and self-ignite, requiring separate storage.

4. Comparison of Flash Point, Fire Point, and Auto-Ignition Temperature

| Parameter | Definition | Requires Ignition Source | Sustained Combustion | Industrial Risk Example |

|---|---|---|---|---|

| Flash Point | Lowest temperature at which a liquid vapor ignites briefly | Yes | No | Solvent or paint warehouse |

| Fire Point | Lowest temperature at which combustion continues after ignition | Yes | Yes | Paint drying lines, lubricating oil production |

| Auto-Ignition Temperature | Lowest temperature for self-ignition without external flame | No | Yes | Coal pile, lithium battery storage |

Generally speaking:

Flash Point < Fire Point < Auto-Ignition Temperature

These three values form the combustion risk curve for materials and serve as critical references for designing fire and explosion prevention, ventilation, and temperature control systems.

5. Key Industrial Protection Measures

Temperature Control:

Store materials at least 10°C below their flash point. High-temperature equipment should have multiple temperature limits and alarms.

Static Electricity & Grounding:

Ensure equipment is grounded in processes like fueling, mixing, and spraying to prevent ignition from static electricity.

Inert Gas Protection:

For low flash point liquids (e.g., toluene, ether), nitrogen gas can be used for protection.

Ventilation & Monitoring:

Install combustible gas detectors with alarm thresholds set at 25% of the lower explosive limit (LEL).

Employee Training & Emergency Procedures:

Personnel should be familiar with flash point, fire point, and auto-ignition temperature values, and know how to respond to emergency cooling and firefighting measures.

6. Conclusion

Although flash point, fire point, and auto-ignition temperature seem like just three numerical values, they determine the safety limits of a facility. Understanding and applying these parameters in design, storage, transportation, and operations is key to preventing fires and explosions, and ensuring the safety of lives and assets.