Introduction

A globe valve is a widely used fluid control valve designed to start, stop, and regulate fluid flow. This article provides a detailed overview of the globe valve, its working principles, structural features, sealing performance, fluid control characteristics, operation, maintenance, and applications in various industries.

I. Working Principle of Globe Valves

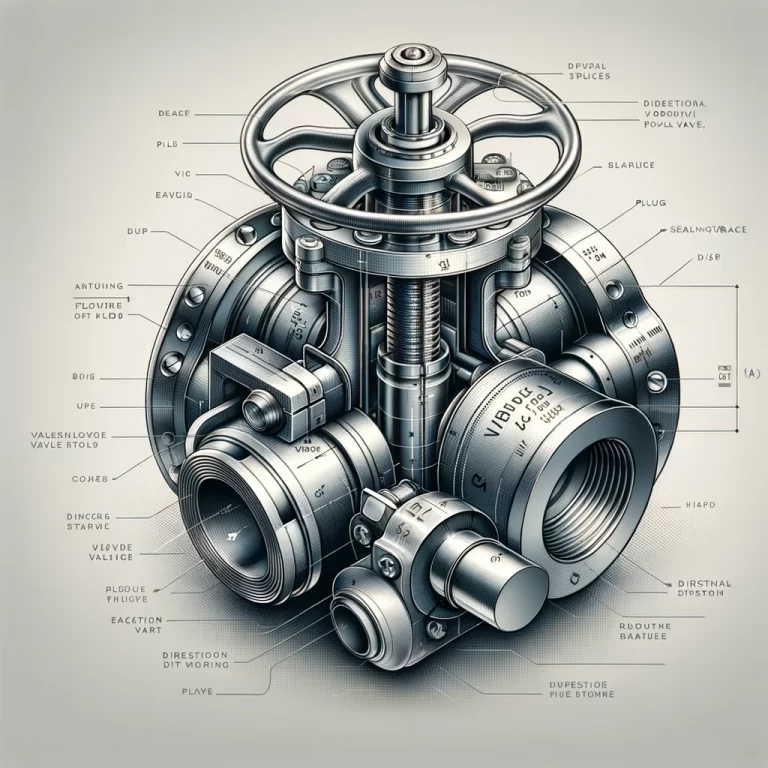

Definition: A globe valve controls fluid flow using a plug-shaped disk that moves linearly in line with the center of the fluid. It generally includes a flat or tapered sealing surface. Globe valves come in several types depending on usage needs, such as straight-flow, direct-current, angle, and right-angle forms, and may be categorized by construction as integral or non-assembled.

Operating Mechanism: The globe valve opens and closes by raising or lowering a valve stem connected to the valve plug (disk), which varies the distance between the valve plug and seat. When the fluid flows upward, the pressure causes the pistons to move, raising the valve stem and opening the valve. Conversely, when the fluid flows downward, increased pressure moves the pistons and inclines the disk, closing the valve.

Example: In a heating system, a globe valve can control the flow of hot water to regulate temperature precisely by adjusting the position of the valve plug.

II. Structural Features of Globe Valves

Simplicity: Globe valves have a relatively straightforward structure, mainly consisting of a valve body, disk, and stem, making them easy to manufacture and maintain.

Directional Flow: The installation of a globe valve is direction-specific, with the medium typically flowing from beneath the disk to exit from the top. This design reduces wear on the disk and enhances sealing performance.

Limitations: Globe valves are not suitable for mediums containing solid particles, highly viscous substances, or mediums that are prone to solidification or crystallization.

Example: In a water treatment plant, globe valves are often used for clean water applications where the fluid is free of solid impurities.

III. Sealing Performance

Enhanced Sealing: During opening and closing, there is no relative sliding between the disk and sealing surface, which minimizes wear and extends the sealing surface’s lifespan.

Dual-Seal Design: Some globe valves use a dual-seal system combining fluororubber O-rings and V-shaped PTFE (Polytetrafluoroethylene) packing to ensure zero leakage.

Example: In a chemical plant handling corrosive fluids, the high sealing performance of a globe valve with dual-seal design ensures that no harmful substances escape, maintaining both safety and efficiency.

IV. Fluid Control Characteristics

Flow Regulation: Although primarily designed for full open and close operations, globe valves can, in some cases, regulate flow by rotating the valve stem. However, their precision in flow regulation is relatively low compared to dedicated throttling valves.

Fluid Resistance: Due to the curved path within the valve body, globe valves have relatively high fluid resistance and therefore higher energy consumption. For applications where low fluid resistance is crucial, alternative valves may be preferred.

Example: In a ventilation system, a globe valve may be used in less critical flow regulation roles due to its moderate control precision but may not be ideal for high-efficiency airflow systems requiring minimal resistance.

V. Operation and Maintenance

Operating Torque: Globe valves require significant torque to open and close, often needing tools for operation, as the process can be effort-intensive and time-consuming.

Ease of Maintenance: Due to their simple structure, globe valves are easy to repair or replace. The sealing components, including the valve seat and disk, are accessible without detaching the valve from the pipeline, facilitating on-site maintenance.

Example: In a municipal water supply network, maintenance teams can quickly replace worn sealing components on a globe valve without having to dismantle extensive pipework, reducing system downtime.

VI. Applications of Globe Valves

Fluid Control: Globe valves are commonly used to control various fluids, including gases, liquids, and corrosive mediums. They are especially effective in scenarios demanding strict sealing requirements.

Pipeline Systems: Widely applied in water supply, drainage, and exhaust systems, as well as chemical pipelines, oil, and natural gas, globe valves play a key role in fluid isolation or flow initiation.

Industrial Equipment: Globe valves are used in boilers, heaters, compressors, heat exchangers, and pump stations, ensuring safe and efficient operation by controlling fluid flow in these high-stakes environments.

High-Pressure and Low-Temperature Media: Globe valves are suitable for high-pressure, low-temperature media, such as the high-pressure pipes in thermal and nuclear power plants.

High Sealing Requirements: With excellent sealing performance, globe valves meet the stringent demands of environments requiring leak-free operation.

Small Valves: Due to their precise control, small-scale globe valves are utilized in specialized applications, such as needle valves and instrument valves, where accurate fluid flow control is essential.

Building Systems: Globe valves are extensively used in construction for HVAC systems, water supply, and fire control, managing the flow of liquids and gases in both internal and external building systems.

Chemical and Petroleum Industries: Known for their durability against corrosion and high temperatures, globe valves are crucial in controlling fluid processes in chemical production and petroleum systems.

Example: In petrochemical refineries, globe valves control the flow of heated and pressurized liquids through reactors and distillation towers, ensuring precise handling of high-risk fluids.

Conclusion

Globe valves are vital components in fluid control, functioning by a linear movement of the valve plug along the centerline to block and regulate flow. They offer simple construction, effective sealing, and directional flow characteristics, though they also have a higher fluid resistance compared to other valve types. Globe valves are widely applicable across industries, from industrial plants and energy facilities to building systems and chemical processing. Choosing and implementing globe valves should consider the specific requirements and conditions of the application to ensure optimal performance.