Pulse signals play a crucial role in thermal control systems, particularly in ensuring precise control, monitoring, and optimization of temperature and heat transfer processes. Their versatility and efficiency make them indispensable across a range of industries, including aerospace, electronics, and manufacturing. Below is a detailed exploration of how pulse signals are utilized in thermal control systems.

1. Temperature Regulation Systems

Pulse signals are commonly employed in temperature control to achieve high precision and efficiency. One notable technique is Pulse Width Modulation (PWM):

- PWM for Heating or Cooling Devices

PWM is used to control the power output of heaters or cooling devices. By adjusting the duty cycle (the proportion of time the signal is “on” versus “off”), the system can deliver varying levels of power. For example:- A high duty cycle provides more heating or cooling.

- A low duty cycle conserves energy while maintaining stable temperatures.

- Advantages of PWM in Thermal Control

PWM provides fast response times, minimizes power loss, and ensures smoother temperature transitions. This is particularly useful in systems requiring tight temperature tolerances, such as semiconductor manufacturing or laboratory equipment.

2. Sensor Signal Processing

Pulse signals are critical in the operation and calibration of thermal sensors, including thermistors, thermocouples, and infrared sensors. Key applications include:

- Sensor Calibration

Pulse signals are used to test and adjust the dynamic response of sensors. This ensures that the sensors accurately measure rapid temperature changes without lag. - Timed Sampling

By using pulse signals as triggers, temperature readings can be taken at specific intervals. This approach reduces noise and enhances the accuracy of temperature measurements.

3. Transient Heat Analysis

Pulse signals are invaluable in studying transient thermal phenomena, providing insights into materials’ heat transfer properties and system dynamics:

- Thermal Conductivity Testing

A heat pulse is applied to a material, and its thermal diffusion behavior is measured. This method helps determine thermal conductivity and diffusivity, crucial for material science and engineering. - Dynamic Thermal Response

Pulse signals simulate sudden heat inputs to evaluate how quickly a system reaches thermal equilibrium. This analysis is essential for designing systems with minimal thermal lag, such as high-speed electronics or aerospace components.

4. Thermal Protection and Alarm Systems

Pulse signals are fundamental in detecting anomalies and safeguarding thermal systems:

- Overheating Alarms

Thermal sensors generate pulse signals when the temperature exceeds a predefined threshold, triggering visual or audible alarms. This is common in industrial furnaces, transformers, and HVAC systems. - Flow Monitoring

Pulse signals can monitor the flow of cooling fluids or air. For instance, a lack of periodic pulses from a flow sensor might indicate a blockage, ensuring timely intervention to prevent overheating.

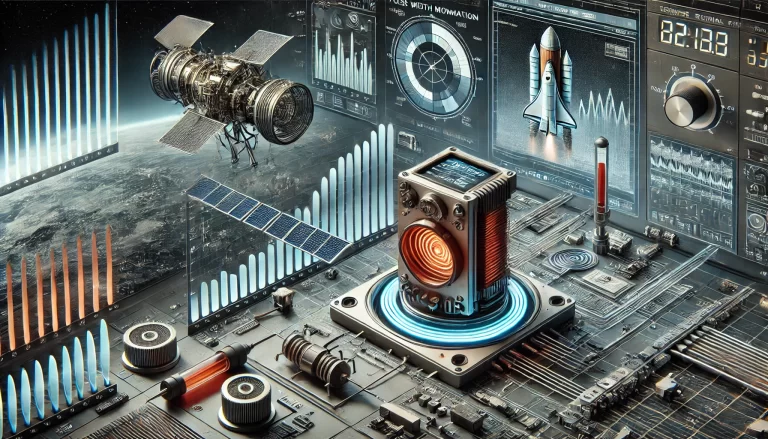

5. Aerospace and Satellite Thermal Control

Pulse signals are widely used in the highly demanding field of aerospace and satellite thermal control, where precision and reliability are critical:

- Heater and Radiator Control

Pulse signals control the operation of onboard heaters and radiators. By modulating their activation cycles, satellite thermal systems maintain optimal operating temperatures for instruments and components. - Energy Optimization

Pulse signals allow thermal control systems to minimize power consumption, an essential factor in satellites with limited energy resources.

6. Thermal System Modeling and Simulation

Pulse signals play a key role in the design, analysis, and validation of thermal systems:

- Input-Output Analysis

Applying a pulse signal to a thermal system and analyzing the response helps engineers verify system models and fine-tune parameters such as time constants and thermal inertia. - System Identification

Pulse signals aid in determining a system’s dynamic properties, including heat capacity and resistance. This information is critical for creating accurate simulations and optimizing system performance.

Conclusion

Pulse signals are integral to the functionality and efficiency of modern thermal control systems. From precise temperature regulation to dynamic heat analysis and fault detection, their applications span a wide array of industries. As technology advances, pulse signal techniques will continue to evolve, enabling even more sophisticated thermal control solutions. Whether in aerospace, manufacturing, or research, the effective use of pulse signals ensures reliable, efficient, and cost-effective thermal management.