1. Why is Air Tightness Important?

Whether it’s a new energy vehicle battery pack, a high-pressure gas pipeline, or a semiconductor vacuum etching machine, their operational stability hinges on an invisible parameter—air tightness.

Air tightness testing is not simply about detecting air leaks; it’s a systematic safety validation and process control method. It determines whether:

A leak in a vacuum chamber leads to chip production failure.

A gas pipeline leakage could cause a fire.

Poor sealing in medical equipment may lead to contamination or safety risks.

2. Why Semiconductor Equipment is Most Sensitive to “Leaks”

In the semiconductor industry, many processes are conducted under vacuum or high-purity gas environments. Gases such as hydrogen, ammonia, and fluorides are commonly used—gases that are flammable, corrosive, or toxic.

Even a tiny leak can cause these gases to escape or allow air to enter. This issue not only directly affects production yield, such as contamination of wafer surfaces or failure in chemical reactions, but also poses significant safety risks. A gas leak could result in fire or poisoning accidents. Additionally, the long-term intrusion of corrosive gases damages the precision equipment, shortening its lifespan and increasing maintenance costs. In severe cases, it could lead to entire production lines being shut down.

As a result, semiconductor manufacturing has extremely strict air tightness requirements, often measured by standards such as “less than one-billionth of a cubic meter per second” for leak rates. In industries such as aerospace, semiconductors, new energy, medical, and refrigeration, air tightness testing plays a more critical role than performance testing—it is the “first line of defense” for product quality and the foundation of industrial safety.

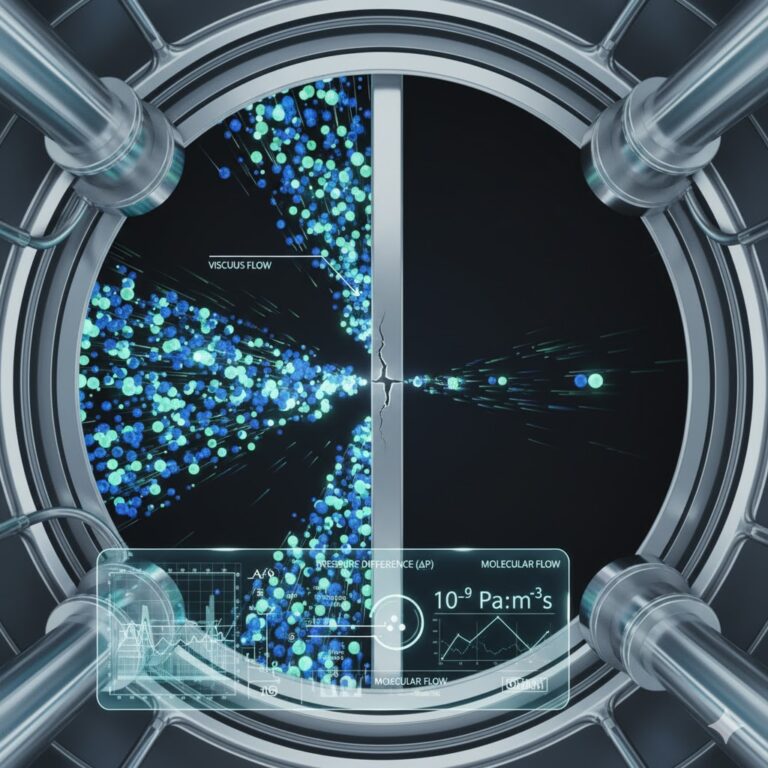

3. The Microscopic Science of Gas Flow

To understand air tightness testing, it’s important to first grasp the physical phenomenon of gas leakage. On a microscopic level, gas molecules are in constant, high-speed motion. When there is a pressure, concentration, or temperature difference within the system, gas molecules diffuse through any available path.

Leakage can occur in three ways:

Viscous Flow: Larger leaks where gas flows like a fluid.

Molecular Flow: Extremely small leaks where gas molecules pass through one-by-one.

Transitional Flow: A mix of both.

Semiconductor equipment is mostly in a vacuum state, so the primary focus is on detecting molecular flow leakage, with precision requirements as high as 10⁻⁹ Pa·m³/s or even higher.

4. Industry-Specific Standards for Leak Rate

| Application | Air Tightness Level (Leak Rate) | Detection Pressure | Detection Methods | Key Features |

|---|---|---|---|---|

| Semiconductor Vacuum Equipment | ≤ 10⁻⁹ Pa·m³/s | 10⁻³~10⁻⁶ Pa | Helium mass spectrometry, Pressure rise method | Ultra-high vacuum, highest precision |

| New Energy Battery Packs | ≤ 10⁻⁶ Pa·m³/s | Atmospheric pressure | Helium leak test, Pressure drop method | Explosion-proof, waterproof, coolant leak-proof |

| Automotive Fuel Systems | ≤ 10⁻⁴ Pa·m³/s | Atmospheric pressure ~2 MPa | Pressure differential, Bubble method | Mass testing, cost-sensitive |

| Medical Devices | IP67 and above | Atmospheric pressure | Ultrasound, Helium leak test | Prevent contamination, prevent liquid infiltration |

| Aerospace | ≤ 10⁻¹⁰ Pa·m³/s | Vacuum | Helium mass spectrometry dual-mode testing | Involves safety and extreme conditions |

Each industry’s “leak rate standard” reflects a different balance of reliability and risk management.

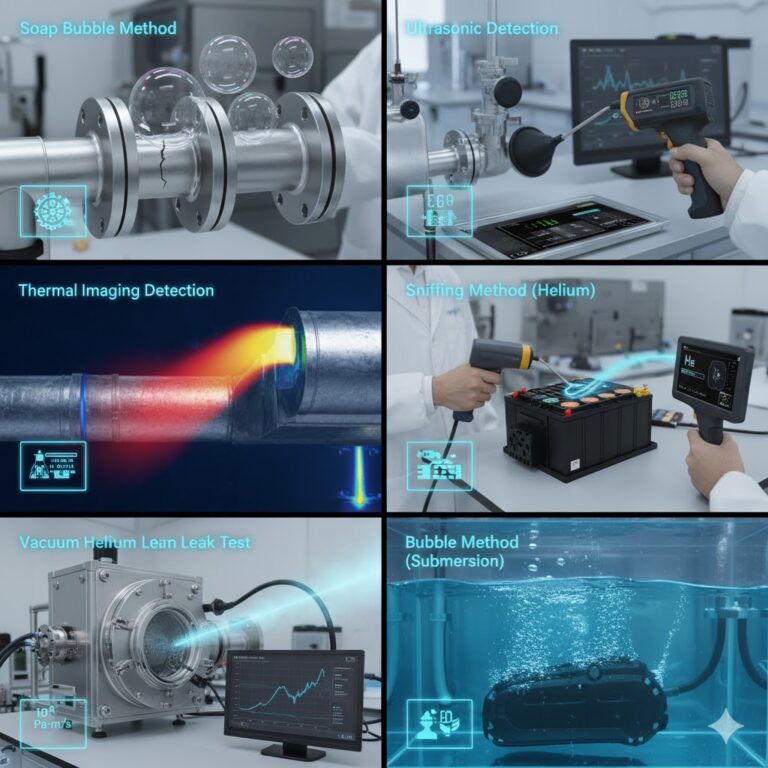

5. Common Air Tightness Testing Methods

When selecting a testing method, factors like accuracy, speed, cost, and repeatability must be considered.

Soap Bubble Method:

This is a basic visual detection method where soap water or special leak detection fluid is applied to suspected leak points to observe if bubbles form. While simple and intuitive, it lacks quantitative analysis and is less sensitive to small leaks.Ultrasonic Detection:

This method captures sound waves generated by turbulent flow at leak points using an ultrasonic leak detector. The frequency of these waves increases with the Reynolds number of turbulence. It allows for remote, non-contact detection but can be influenced by environmental noise.Thermal Imaging Detection:

Gas leaks cause temperature changes due to expansion or absorption of heat. Thermal imaging cameras quickly detect these temperature anomalies. This method is commonly used in HVAC systems and refrigerant pipelines.Halogen Method:

This method uses halogen gases (e.g., fluorochloromethane) as tracer gases, detecting leaks based on changes in the halogen signal. With sensitivity up to 10⁻⁵ Pa·m³/s, it’s suitable for high-precision sealing tests, but precautions for safety and environmental impact are necessary due to the corrosive nature of halogen gases.Sniffing Method (Positive Pressure Helium Leak Test):

Helium gas is used as a tracer in this high-sensitivity method. After injecting helium into the system, a “sniffing gun” detects any helium concentration change externally. This method is commonly used for battery enclosures, vacuum chambers, and high-seal components due to its high precision.Vacuum Helium Leak Test:

Vacuum chambers are pumped, and helium gas is sprayed externally. Any microleakage will allow helium atoms to enter the system, detected by a mass spectrometer. This method achieves precision up to 10⁻⁹ Pa·m³/s and is the standard in the semiconductor and aerospace industries.Bubble Method:

Parts are inflated and submerged in water. Bubbles indicate a leak. Suitable for non-precision systems, such as pipes and valves.Water Pressure Method:

Pipes are filled with water under pressure, and any pressure drop is monitored to detect leaks. Commonly used for pipeline and hydraulic system checks.

6. Key Control Points in Testing System Design

Temperature Compensation & Algorithm Calibration:

Temperature variations can cause changes in gas volume and pressure. If not corrected, false positives or missed leaks could occur.Sealing Fixture Matching:

The detection fixture must align precisely with the product’s geometry; otherwise, “false leaks” can occur.System Stability & Noise Suppression:

Vibrations and fluctuations in gas sources can interfere with micro-leak detection signals.Data Traceability & Digital Integration:

Modern detection equipment often integrates with MES systems to enable process documentation and trend analysis.

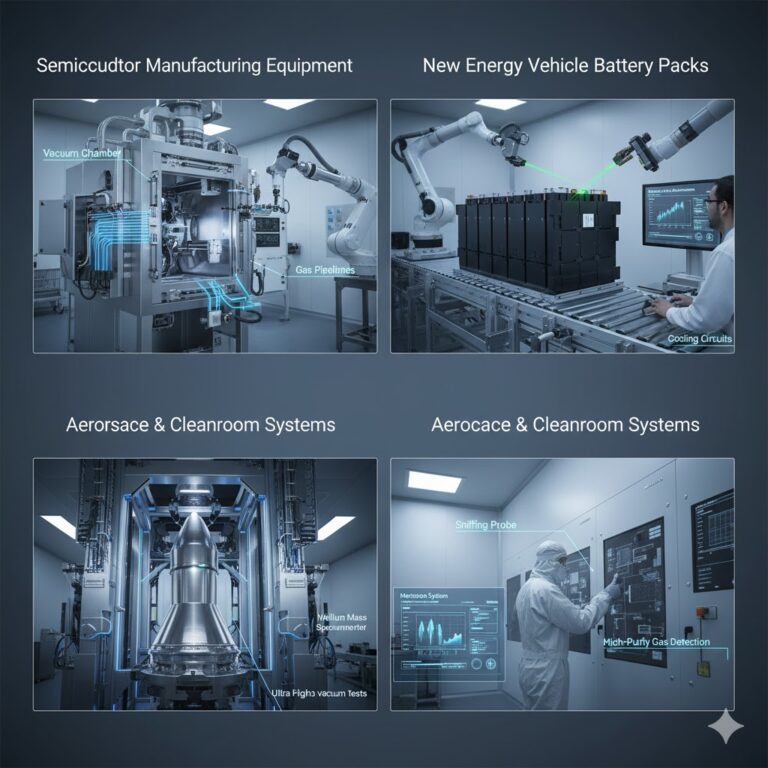

7. Applications of Air Tightness Testing

Semiconductor Manufacturing Equipment:

Testing of vacuum chambers, gas pipelines, valves, and O-ring seals.Lithium Battery Packs:

Leak detection of cell enclosures and cooling circuits.New Energy Vehicles:

Waterproof and air tightness verification of electric drive systems.Cleanroom Systems:

Micro-leak detection in high-purity gas delivery systems.

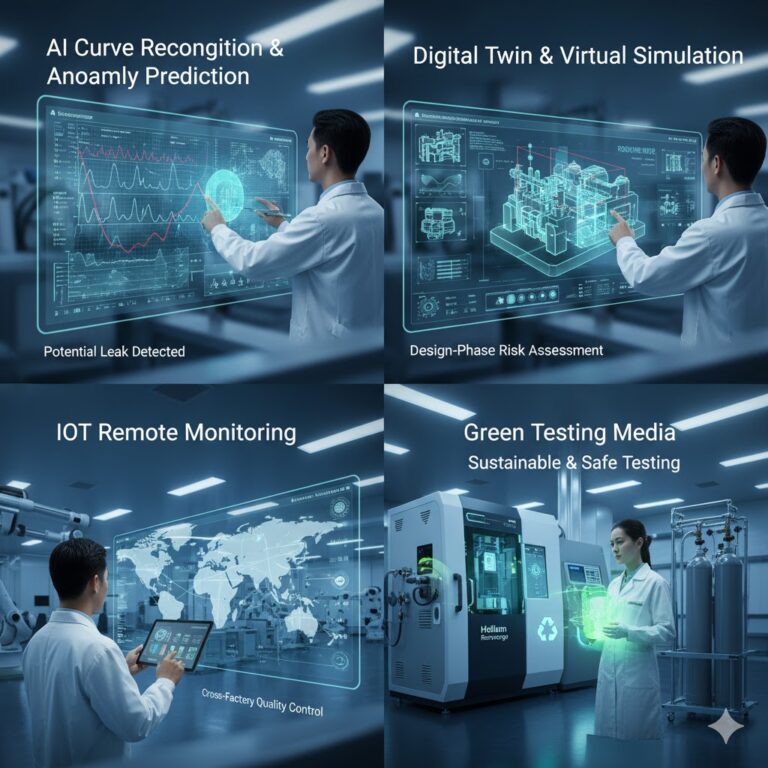

8. From “Testing” to “Smart Testing”

Air tightness testing is evolving from a result-driven approach to process-aware testing. The future includes:

AI Curve Recognition and Anomaly Prediction:

Using machine learning algorithms to analyze pressure curves, automatically identifying anomaly patterns and predicting leaks ahead of time.Digital Twin and Virtual Simulation:

Reproducing leak models in virtual environments to predict sealing risks during the design phase.IoT Remote Monitoring:

Real-time uploading of test data to the cloud for cross-factory quality control.Green Testing Media:

Promoting the use of helium recovery and hydrogen-nitrogen mixed alternatives for environmentally friendly and safe testing.

In the future, testing will no longer be just about “finding leaks” but will evolve into smart alerts and closed-loop process control.

9. Conclusion

The ultimate goal of air tightness testing is not just to detect leaks but to achieve the pinnacle of reliability and safety in industrial systems. From soap bubbles to helium mass spectrometers, and from human observation to AI recognition, each “air tightness test” turns uncertainty into control and potential hazards into data.

Whether it’s the combustion chamber of a rocket engine or the refrigeration pipe in household appliances, every precise air tightness test is a testament to the integrity of modern manufacturing. In the future, air tightness testing will no longer be a hidden technology but will become a “safety language” for the era of intelligent manufacturing.