Absolute pressure transmitters and vacuum (or negative gauge) pressure transmitters are widely used in industrial applications. The key differences lie in their reference baseline, measurement principle, and application scenarios. Below is a detailed comparison.

1. Definitions and Measurement Principles

| Type | Definition | Reference Baseline | Measurement Range |

|---|---|---|---|

| Absolute Pressure Transmitter | Measures the pressure relative to a perfect vacuum (zero pressure). | Absolute vacuum (0 Pa) | 0 Pa to upper range limit (e.g., 0–100 kPa) |

| Vacuum (Gauge) Pressure Transmitter | Measures pressure below atmospheric pressure (negative gauge pressure), referenced to local atmospheric pressure. | Local atmospheric pressure (101.325 kPa) | -100 kPa to 0 kPa (or higher) |

2. Key Differences

| Comparison Aspect | Absolute Pressure Transmitter | Vacuum (Gauge) Pressure Transmitter |

|---|---|---|

| Reference Pressure | Absolute vacuum (zero absolute pressure) | Current atmospheric pressure |

| Output Signal | 0 kPa represents absolute vacuum | 0 kPa represents atmospheric pressure; negative values indicate vacuum |

| Typical Applications | Eliminates atmospheric pressure influence | Measures vacuum relative to atmosphere |

| Environmental Impact | Unaffected by atmospheric pressure variations | Affected by atmospheric pressure fluctuations (requires periodic calibration) |

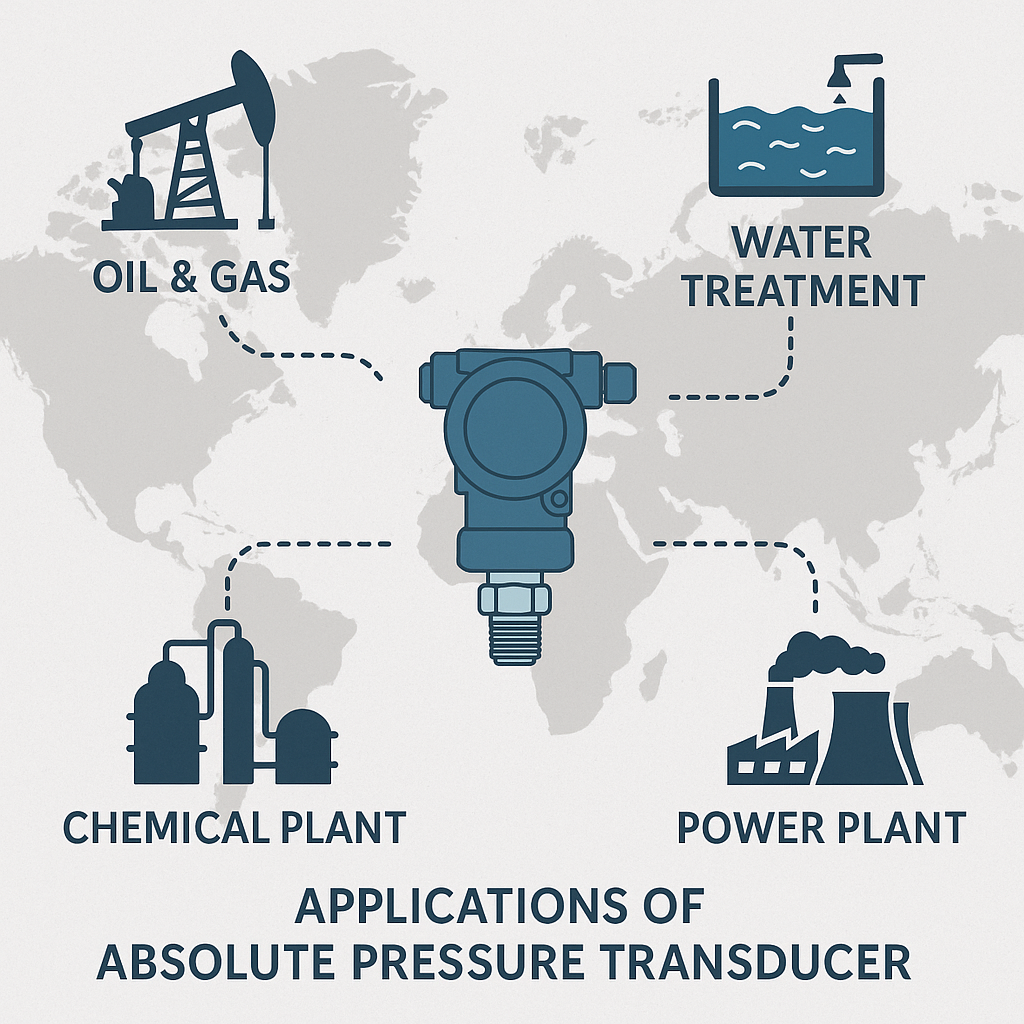

3. Typical Applications

Absolute Pressure Transmitter

Sealed System Pressure Monitoring: Reactors, distillation columns where atmospheric fluctuations must be excluded.

Meteorology & Aviation: Measuring barometric pressure and altitude.

Vacuum Systems: High-vacuum environments such as semiconductor manufacturing and vacuum coating.

Deep Pressure Environments: Monitoring underwater or underground pressures.

Vacuum (Gauge) Pressure Transmitter

Industrial Vacuum Systems: Vacuum packaging machines, central vacuum systems.

Medical Devices: Ventilators, negative pressure isolation rooms.

Ventilation Systems: Monitoring negative pressure in ducts or rooms to prevent gas leakage.

Laboratories: Negative pressure reactors and filtration systems.

4. Selection Guidelines

✅ Choose Absolute Pressure Transmitters when:

Measurement is relative to a vacuum baseline.

Atmospheric pressure instability (e.g., in sealed chemical processes) must be excluded.

✅ Choose Vacuum (Gauge) Pressure Transmitters when:

Only negative pressures relative to atmospheric pressure need to be monitored (e.g., HVAC systems).

Atmospheric pressure fluctuations are within acceptable limits.

5. Key Considerations

⚙️ Calibration:

Absolute pressure transmitters require zero-point calibration in a vacuum environment (usually done at the factory).

Vacuum pressure transmitters need periodic calibration to account for atmospheric pressure variations due to weather or altitude changes.

⚙️ Material Compatibility:

For corrosive environments, ensure proper diaphragm and wetted part materials (e.g., 316L stainless steel, Hastelloy).